Thermal #2: Heat flux

analysis of a composite modular wall

Introduction:

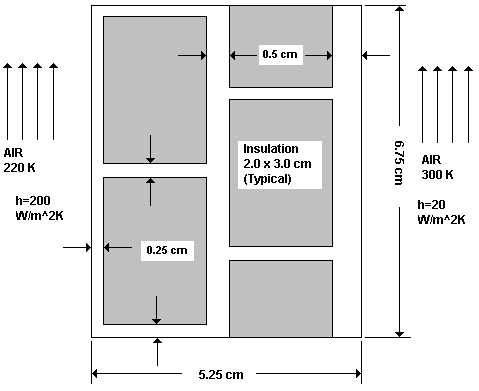

In this

example you will determine the heat flux through the composite modular

wall shown in the figure.

Physical Problem:

A

composite wall is widely used in cold places to insulate buildings from

the cold outside surroundings. It typically consists of insulating

material packed inside a wall. The insulating material is usually in two

layers and is staggered. In this problem we will model a section of such

a wall and determine the heat flux through the wall. This gives an

estimate of the amount of heat that needs to be supplied to maintain the

room temperature.

Problem Description:

|

The outer material

of the composite wall is steel with thermal conductivity of 20 W/m K

|

|

The insulating

material has a thermal conductivity of 0.1 W/m K. |

|

Units: Use

S.I. units ONLY |

|

Geometry:

See figure. |

|

Boundary

Conditions:

The bulk

temperature on the left of the wall is 220K, and the Film

Coefficient is 200 W/m2K. On the right side the bulk

temperature is 300K, and the Film Coefficient is 20 W/m2K. |

|

Objective:

|

To determine the

heat flux through the given length of the wall. |

|

To plot the

temperature distribution. |

|

To generate the

vector plot of the heat flux. |

|

|

You are required to

hand in print outs for the above. |

|

Figure:

|

|

IMPORTANT:

Convert all

dimensions and forces into SI units. |

STARTING ANSYS

|

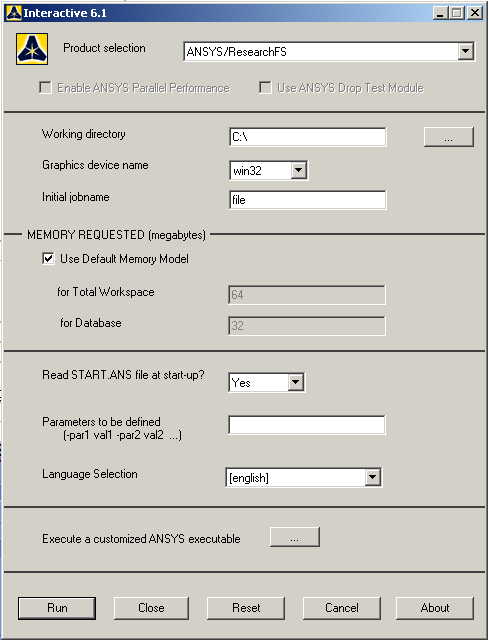

Click on ANSYS

6.1 in the programs menu. |

|

Select

Interactive. |

|

The following menu

that comes up. Enter the working directory. All your files will be

stored in this directory. Also enter 64 for Total Workspace and

32 for Database. |

|

Click on Run.

|

MODELING THE STRUCTURE

|

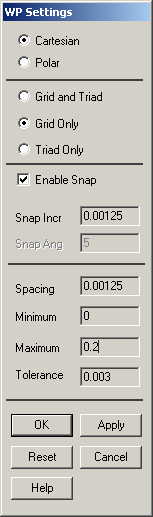

Go to the ANSYS

Utility Menu.

|

Click

Workplane>WP

Settings.

|

|

The following

window comes up: |

|

|

Check the

Cartesian and Grid Only buttons |

|

Enter the values

shown in the figure above. |