|

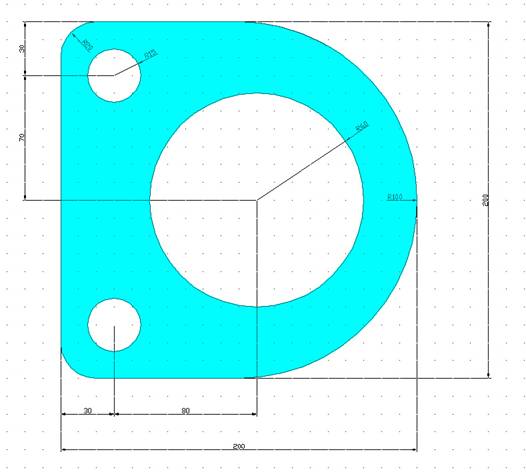

We will model the

bracket as a solid 8 node plane stress element. By a plane stress

element we are assuming that there are no stresses in the thickness

direction of the bracket. |

|

Geometry:

The thickness of the bracket is 3.125 mm |

|

Material:

Assume the structure is made of steel with modulus of elasticity E=200

GPa. |

|

Boundary conditions:

The bracket is fixed at the screw holes. |

|

Loading:

The bracket is loaded at one point in the center of the large hole.

The load is 2000 N. |

|

Objective:

|

Plot deformed

shape |

|

Determine the

principal stress and the von Mises stress. (Use the stress plots to

determine these) |

|

Remodel the

bracket without the fillet at the corner, and see how principal

stress and von Mises stress change. |

|

|

You are required to

hand in print outs for the above. |

|

Figure: |

IMPORTANT:

Convert

all dimensions and forces into SI units

·

Turn on

the keypoint numbering function in the ANSYS Utility Menu.

·

Create

the keypoints to form the area that will become the bracket.

·

Then

connect the keypoints with lines and define an area to form the bracket

master area.

·

Fillet

the lines to form the curve on the right side. Use a fillet radius of

0.1.

·

Create

two areas defined by the fillet curve and the respective corner of the

bracket master area.

·

Create

the Circular areas in the center and left side of the bracket.

·

Subtract the areas defined by the fillet, the center circle, and the two

smaller circles to form the shape of the bracket intended to be

analyzed.

·

Add the

two lines forming the bottom of the circle together to form one arc that

encompasses the lower semicircle of the center circle.

·

Define

the Material Properties of the Steel Element (Elastic Modulus and

Poison’s Ration are the important qualities)

·

Define

the Element Properties as a

Quad 8 node

Structural Solid.

·

In the

Element Type Window, set the option of setting the Plane Stresses to the

thickness. (Hint: in the window it’s the value for K3)

·

Set the

Real Constant Set No. to 1 and the Real Constant for the Plane Stress

with Thickness to 0.03.

·

Mesh

the bracket. (Do so by picking the lines around the outer boundary of

the bracket and setting the element edge length to 0.0125. Next set the

element edge length around the small circles to 0.00125. Then Mesh the

area.)

·

Apply

the boundary conditions. (Structrual Displacement on the edges of the

“screw holes” equal to zero, and a structural force / moment on the

bottom of the large circle equal to –900N in the Y direction.)