Thermal #1: Temperature

distribution in a fin cooled electronic component

Introduction:

In this

example you will learn to model a cooling fin for electronics. This

involves heat generation, conduction and convection.

Physical Problem:

All

electronic components generate heat during the course of their

operation. To ensure optimal working of the component, the generated

heat needs to be removed and thus the electronic component be cooled.

This is done by attaching fins to the device which aid in rapid heat

removal to the surroundings.

Problem Description:

|

For the sake of

simplicity we assume that the electronic circuit is made of copper

with thermal conductivity of 386 W/m K. Also it generates heat at the

rate of 10e6 W. |

|

The enclosing

container is made of steel with thermal conductivity of 20 W/m K.

|

|

The fins are made

of aluminum with thermal conductivity of 180 W/m K. |

|

Units: Use

S.I. units ONLY |

|

Geometry:

See figure. |

|

Boundary conditions:

There is convection along all the boundaries except the bottom, which

is insulated. The Film Coefficient is 50 W/m2K and the Bulk

Temperature is 20oC. |

|

Objective:

|

To determine the

nodal temperature distribution. |

|

To determine the

maximum value of temperature in the component. |

|

|

You are required to

hand in print outs for the above. |

|

Figure:

|

IMPORTANT:

Convert

all dimensions and forces into SI units.

STARTING ANSYS

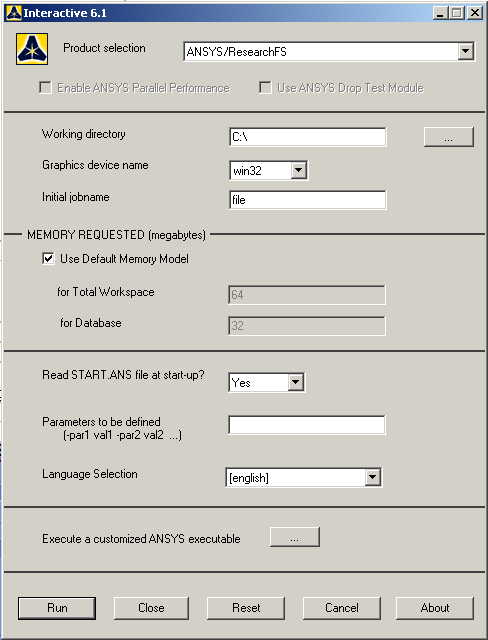

Click

on ANSYS 6.1in the programs menu.

Select

Interactive.

The

following menu that comes up.

Enter the working directory. All your files will be stored in this

directory. Also enter 64 for Total Workspace and 32 for

Database.

Click

on Run.

MODELING THE STRUCTURE

|

Go to the ANSYS

Utility Menu.

|

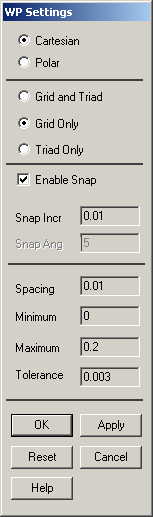

Click

Workplane>WP

Settings.

|

|

The following

window comes up |

|

|

Check the

Cartesian and Grid Only buttons. |

|

Enter the values

shown in the figure below. |

|

Go to the ANSYS

Main Menu

Preprocessor>Modeling>Create>Areas>Rectangle>2 Corners.

|

|

The following

window comes up: |

|

Now we will pick

the end points of the rectangles. |

|

First make the

steel rectangle of dimensions 5cm X 3 cm, i.e. 5 units by 3 units on

the grid. |

|

Next make the

copper square of dimensions 1cm X 1cm. |

|

Next make the

aluminum part by making a rectangle of dimensions 5cm X 2cm and then

creating two smaller rectangles, which can then be subtracted from the

main part to make the fins. |

|

From Preprocessor,

choose

Modeling>Operate>Boolean>Overlap>Areas.

Choose the Steel area and then the Copper area,

then click OK. |

|

From Preprocessor,

choose

Modeling>Operate>Boolean>Glue>Areas.

Choose the Steel area and then the Aluminum area, and then click OK.

The reason why we don’t glue the copper and the steel is that they

overlap. Picture a copper plate resting on the steel area. The steel

and aluminum are connected more intimately, and must be glued

together. |

|

If you cannot see

the complete workplane then go to

Utility Menu>Plot Controls>Pan Zoom Rotate

and zoom out to see the entire workplane.

|

|

The model should

look like the one below. |

MATERIAL PROPERTIES

|

We need to define

material properties separately for steel, aluminum, and copper.

|

|

Go to the ANSYS

Main Menu |

|

Click

Preprocessor>Material Props>Material Models.

In the window that comes up choose

Thermal>Conductivity>Isotropic.

|

|

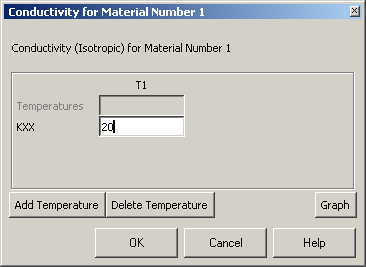

Enter 1 for the

Material Property Number and click OK. The following window comes up.

|

|

Fill in 20

for Thermal conductivity. Click OK. |

|

Now

the material 1 has the properties defined in the above table. This

represents the material properties for steel. Repeat the above

steps to create material properties for aluminum (k=180,

Material number 2), and copper (k=386, Material number 3). Do

this by selecting

Material>New Model

in the “Define

Material Model Behavior” window. |

ELEMENT PROPERTIES

|

SELECTING ELEMENT

TYPE: |

|

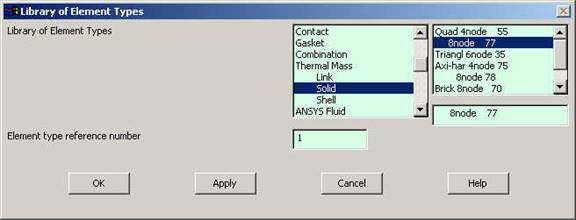

Click

Preprocessor>Element Type>Add/Edit/Delete...

In the 'Element Types' window that opens click on Add... The following

window opens. |

|

Type 1 in

the Element type reference number. |

|

Click on Thermal

Mass Solid and select Quad 8node 77. Click OK. Close the

'Element types' window. |

|

So now we have

selected Element type 1 to be a thermal solid 8node element. The

component will now be modeled with thermal solid 8node elements. This

finishes the selection of element type. |

MESHING

|

DIVIDING THE TOWER

INTO ELEMENTS: |

|

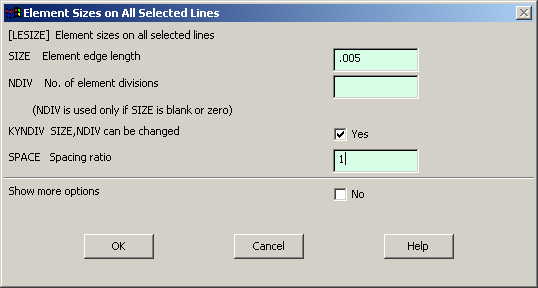

Go to

Preprocessor>Meshing>Size Controls>Manual Size>Lines>All Lines.

In the menu that comes up type 0.005 in the field for 'Element edge

length'. |

|

Click on OK. Now

when you mesh the figure ANSYS will automatically create meshes that

have an edge length of 0.005m along the lines you selected.

|

|

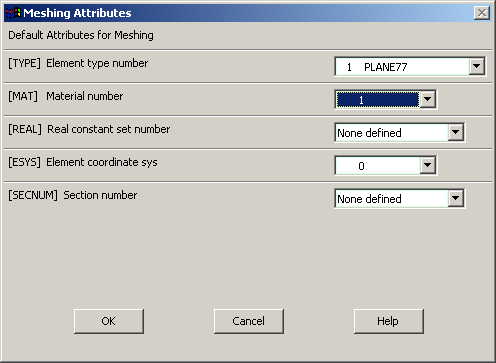

First we will mesh

the steel area. Go to

Preprocessor>Meshing>Mesh Attributes>Default Attributes.

Make sure the window indicates "Material Ref.#1".

The window is shown below. |

|

Now go to

Preprocessor>Meshing>Mesh>Areas>Free.

Pick the steel area and click OK. |

|

Repeat the same

process for the aluminum and copper areas. Make sure you use the

correct material number (2 and 3 respectively) for both the areas.

Also since the steel and the copper areas overlap make sure you pick

the right area. If you choose the wrong area, use

Preprocessor>Meshing>Clear

to undo the previous mesh and then repeat the previous steps. The

meshed area should look like this: |

BOUNDARY CONDITIONS AND

CONSTRAINTS

|

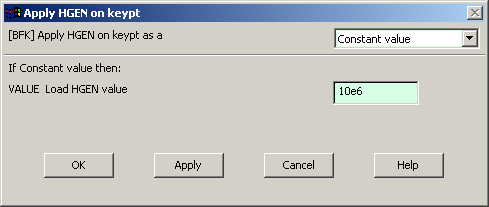

Go to

Preprocessor>Loads>Define Loads>Apply>Thermal>Heat Generate>On

Keypoints.

|

|

Select the corners

of the copper square. Click OK. The following window comes up.

|

|

Enter 10e6

for the HGEN value and click OK. |

|

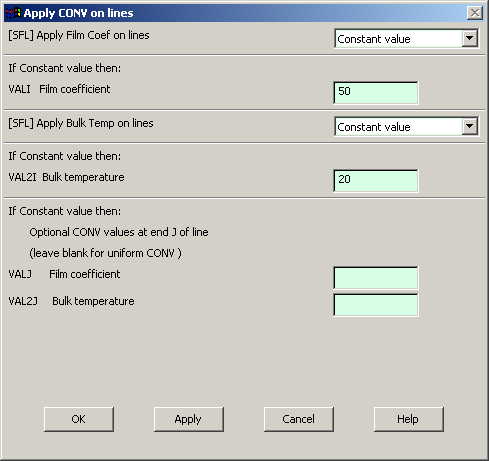

Go to Preprocessor>Loads>Define

Loads>Apply>Thermal>Convection>On Lines.

Pick all the lines on the outside of the object except the bottom one

where the object is considered insulated. Click OK. The following

window comes up. |

|

Enter 50 for

"Film Coefficient" and 20 for "Bulk Temperature" and click OK.

|

|

Now the Modeling of

the problem is done. |

SOLUTION

|

Go to ANSYS

Main Menu>Solution>Analysis Type>New Analysis.

|

|

Select Steady

State and click on OK. |

|

Go to

Solution>Solve>Current LS.

|

|

An error window may

appear. Click OK on that window and ignore it. |

|

Wait for ANSYS to

solve the problem. |

|

Click on OK and

close the 'Information' window. |

POST-PROCESSING

|

Listing the

results. |

|

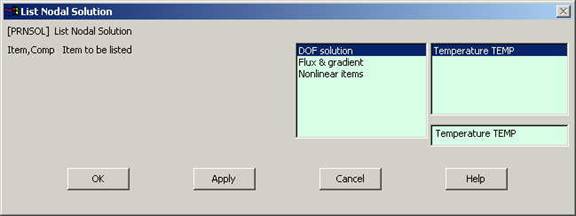

Go to ANSYS Main

Menu

General Postprocessing>List Results>Nodal

Solution.

The following window will come up. |

|

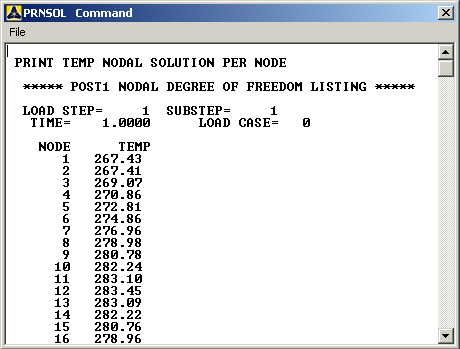

Select DOF

solution and Temperature. Click on OK. The nodal

displacements will be listed as follows. |

|

You will find the

maximum value of temperature at the end of the above table.

|

MODIFICATION

|

You can also plot

the displacements and stress. |

|

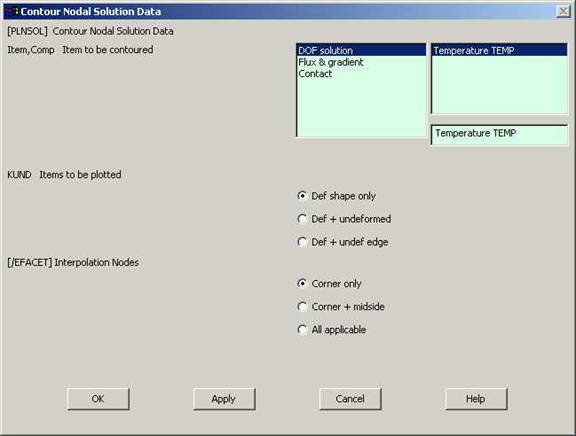

Go to

General Postprocessing>Plot

Results>Contour Plot>Nodal Solution.

The following window will come up: |

|

Select DOF

solution and Temperature to be plotted and click OK. The

output will be like this: |