7. Refine the Mesh

In order to obtain more accurate results, we will refine the previous mesh by

assigning mesh sizes to the lines on the plate. Since the area around the hole

is of greatest interest, when specifying element sizes, it is better to decrease

the line division size as the hole is approached. (More elements near the hole)

However, before refining the mesh, you will have to clear the previous mesh

:

PREPROCESSOR -> -Meshing - Clear

CLEAR -> Areas

CLEAR

AREAS -> Pick all areas.

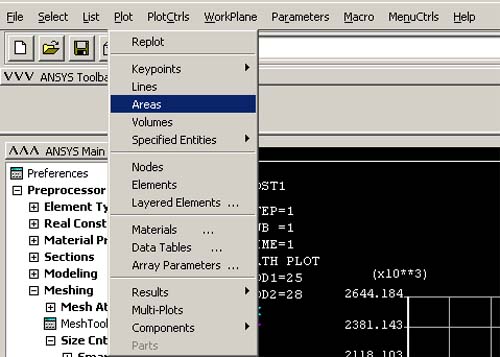

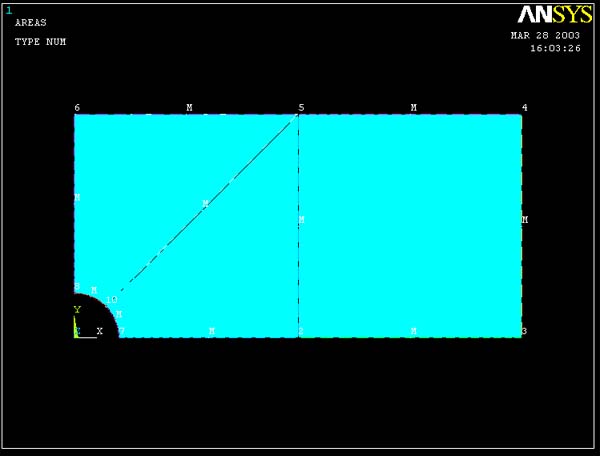

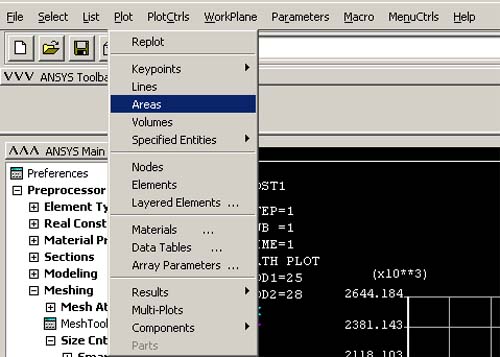

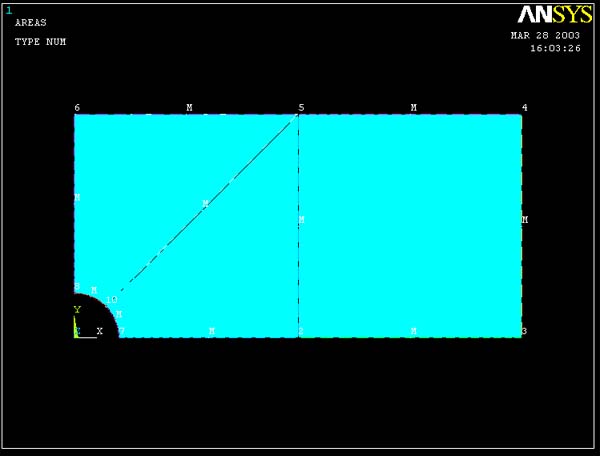

UTILITY

MENU -> Plot - Areas

You have just cleared your previous mesh. Now we will assign new mesh sizes

to the line to create a finer mesh.

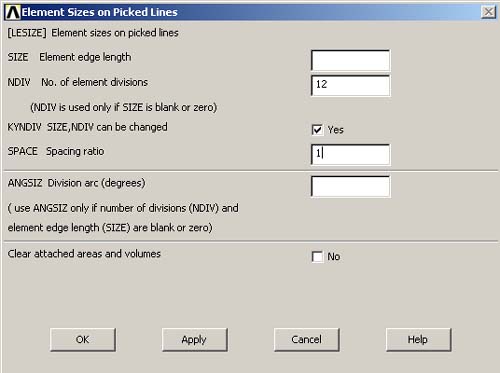

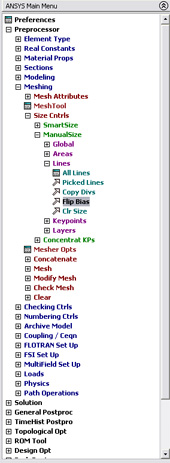

PREPROCESSOR -> -Meshing - Size Cntrls

SIZE CNTRLS -> Lines -Picked Lines

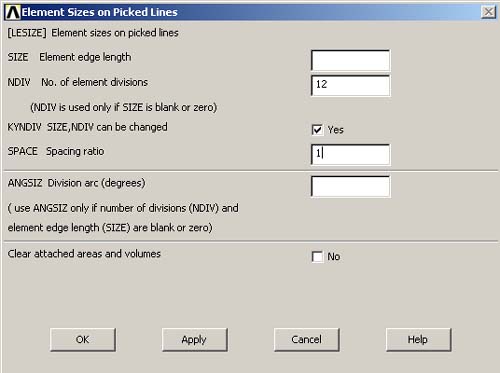

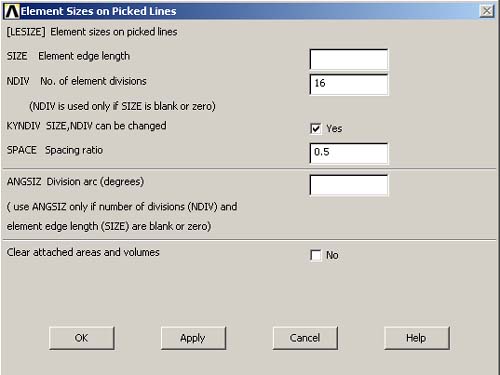

ELEMENT SIZE ON PICKED LINES -> There

are altogether 10 lines on the plate. In the following 4 steps, we will assign

the number of element divisions per line and spacing ratio to each line so

that there will be more elements on the area around the hole, and also to

arrange the elements in a nice order.

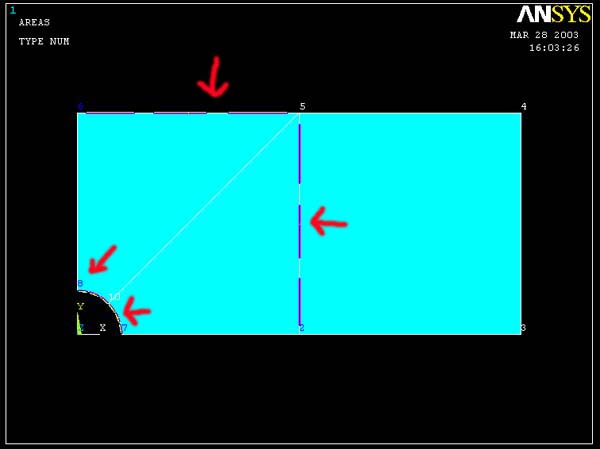

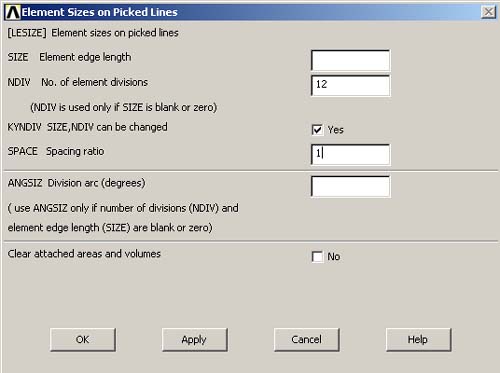

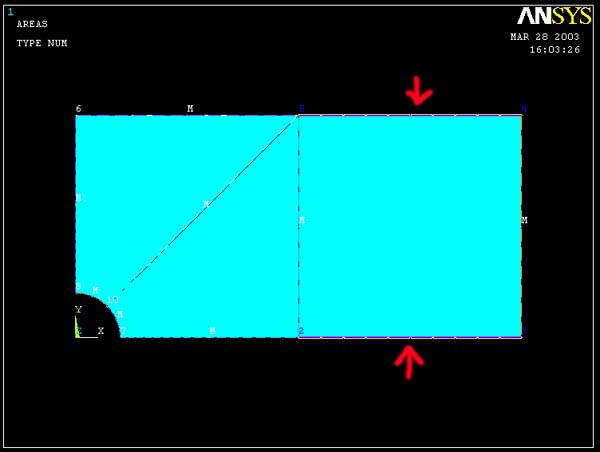

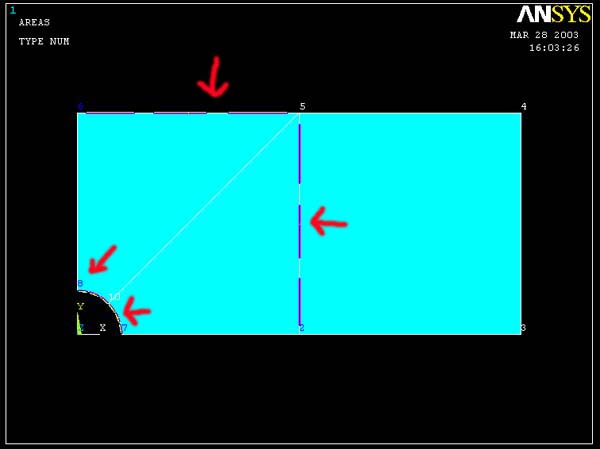

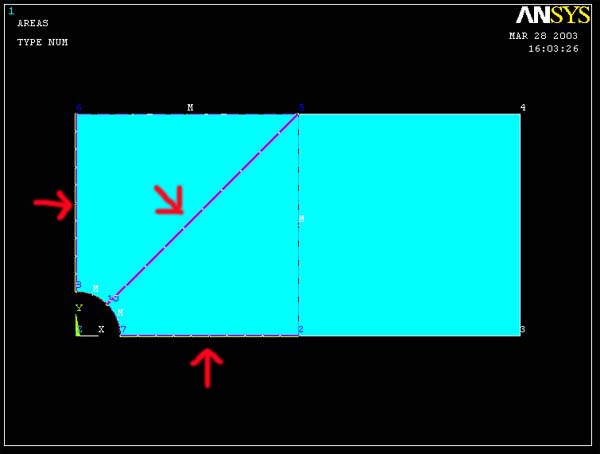

1)

Pick 2 lines on the edge of the hole, and 2 lines on the opposite sides. (See

figure below). Then click APPLY

Enter 12 for number of element divisions per line and 1 for Spacing ratio.Then

click APPLY.

|

Note

: |

NDIV

= If positive, NDIV is the number of element divisions per line. If -1,

NDIV is assumed to be zero element divisions per line

|

| SPACE

= Spacing ratio. If positive, nominal ratio of last division size to first

division size (if > 1.0, sizes increase, if < 1.0, sizes decrease).

If negative, |SPACE| is nominal ratio of center division(s) size to end

divisions size. Ratio defaults to 1.0 (uniform spacing) |

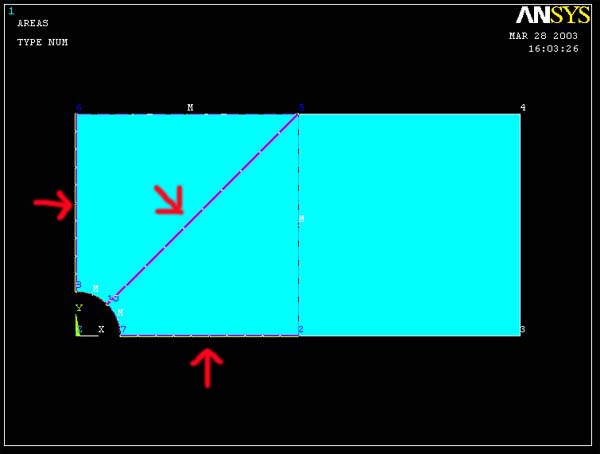

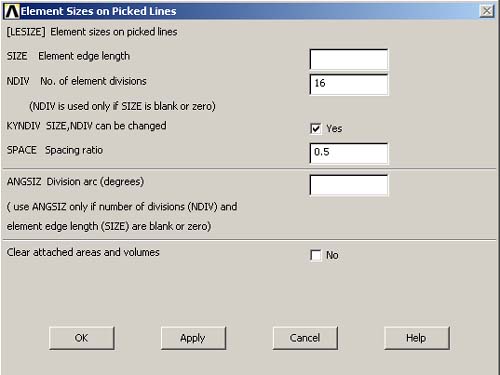

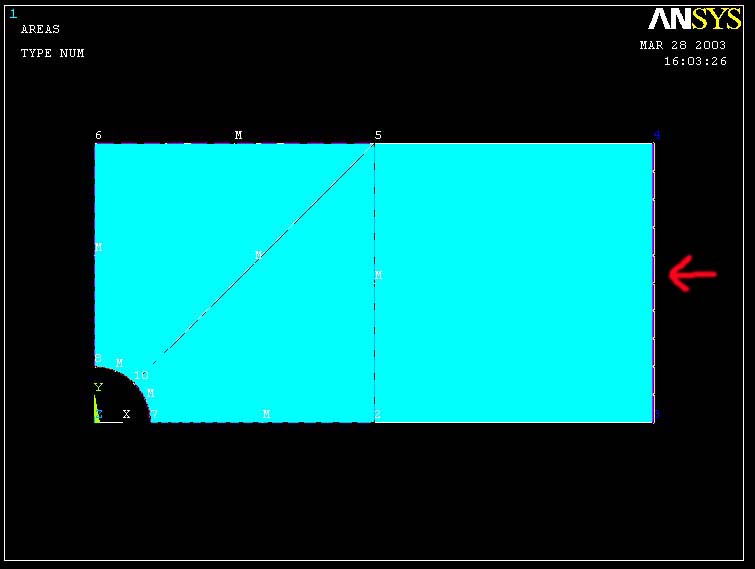

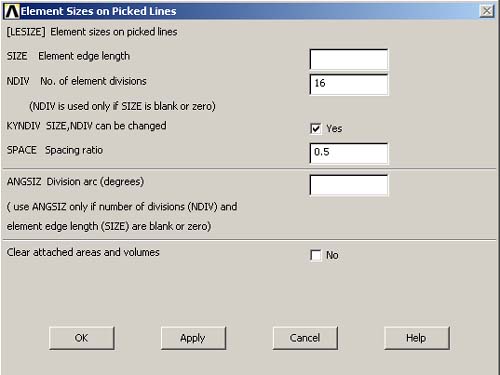

2) Pick the three lines that radiate from the hole. (See Figure below)

Then click APPLY.

Enter 16 for number of element divisions per line and 0.5 for Spacing ratio.

Then click APPLY. (More number of element divisions means more elements near

the hole. Also, specifying a Spacing ratio less than 1 means that the element

sizes decrease as the hole is approached.)

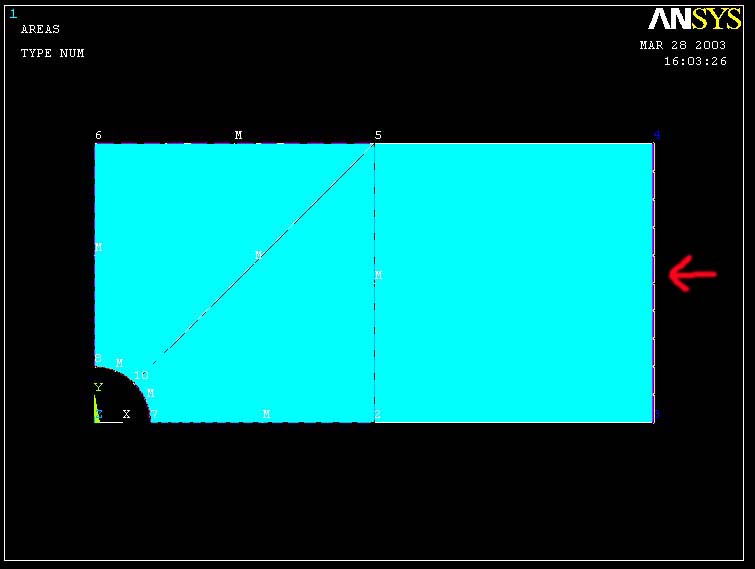

3) Pick the line on the right most edge of the plate. (See Figure) Then

click APPLY.

Enter 12 for number of element divisions per line and 1 for Spacing ratio. Then

click APPLY.

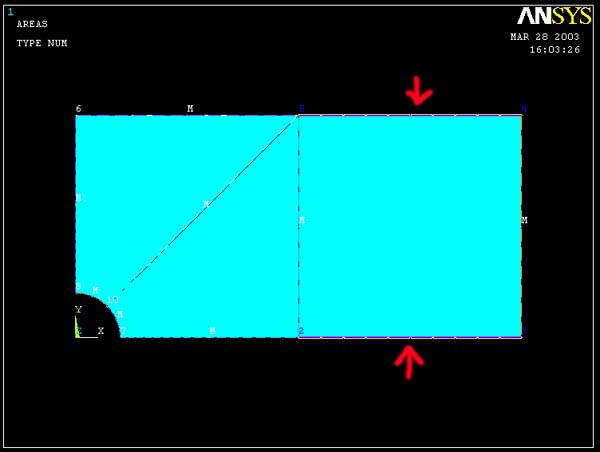

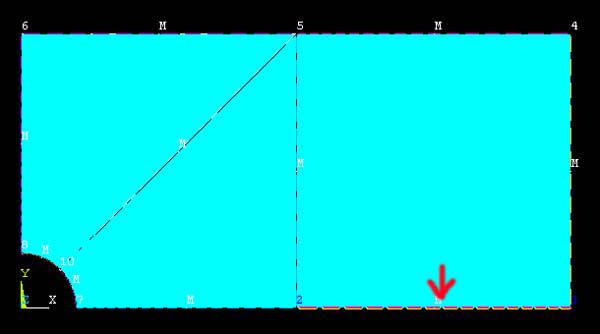

4) Pick the remaining 2 lines. (See Figure) Then click APPLY.

Enter 16 for number of element divisions per line and 0.5 for Spacing ratio.

Then click OK.

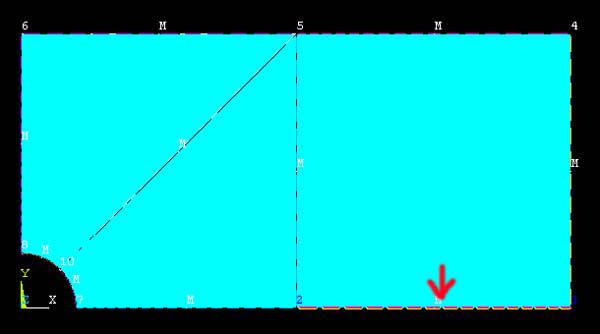

Note that the division sizes on the bottom line decrease as the hole is approached.

This is because the number of keypoints on the left of the bottom line is less

than of the one on the right, when 0.5 was input for the spacing ratio, ANSYS

decreased the division sizes from the left to the right on the line. But since

we need the opposite result, the next step will lead you to flip the line division

which is what we will do next.

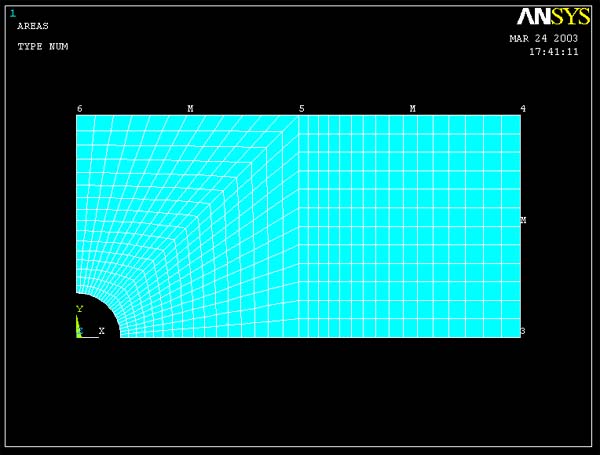

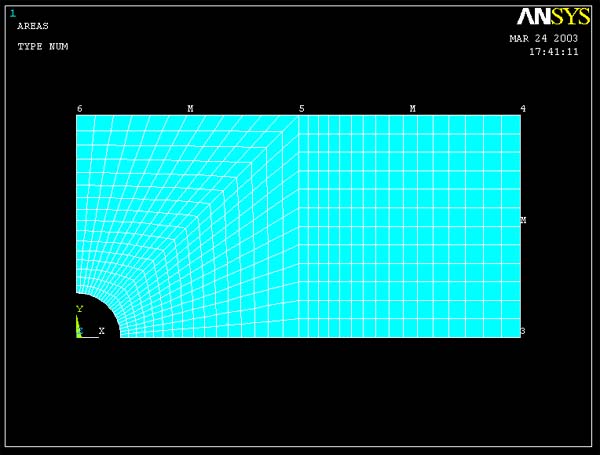

After meshing,

you should see the figure below.

Note that

after the lines are meshed, there will be letter M's

located beside the lines indicate that they are already meshed. Also notice

that when the lines are picked, ANSYS shows the numbers

of keypoints of those lines in blue. These numbers are important when

you assign the spacing ratio. If the spacing ratio is less than one, element

sizes decrease along the line from the former keypoint to latter keypoint.

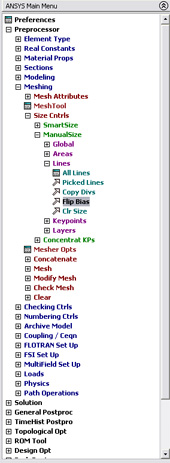

Now, we will flip

the line division using the flip bias command.

SIZE

CNTRLS -> Flip Bias

FLIP LINE BIAS -> Pick the bottom line that needs

to be flipped.

Click OK.

Now the plate is ready to be meshed.

PREPROCESSOR -> -Meshing -Mesh

MESH -> Areas -Mapped

MAPPED

-> 3 or 4 sided

MESH

AREAS -> Pick all areas.

MESH

AREAS -> OK.

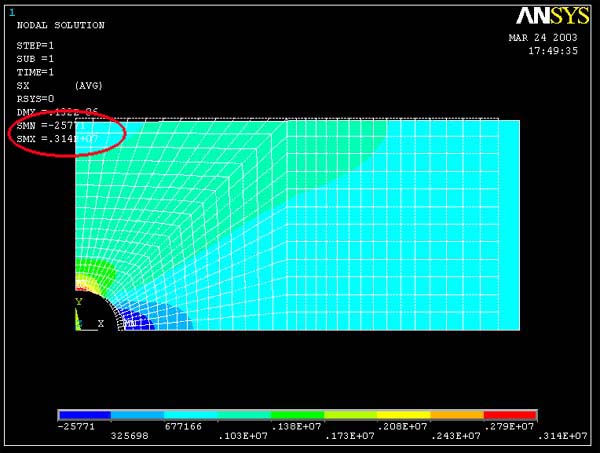

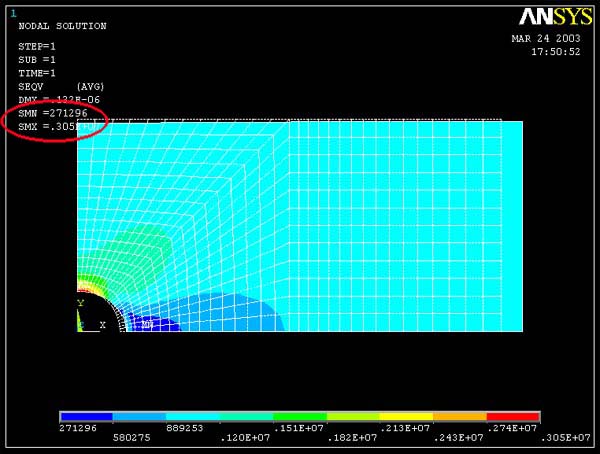

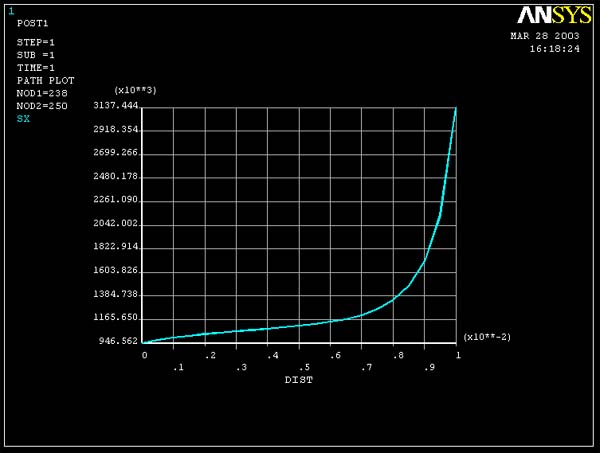

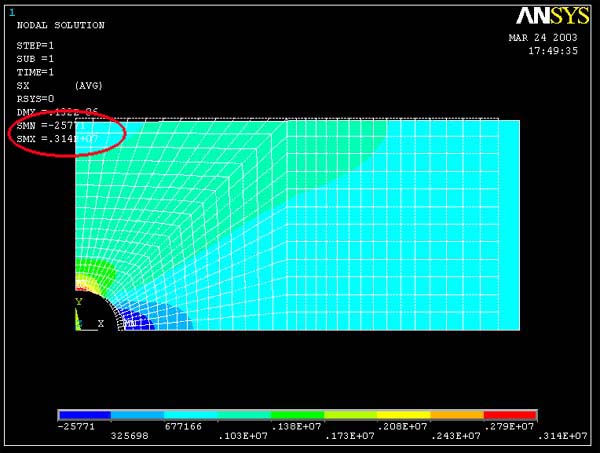

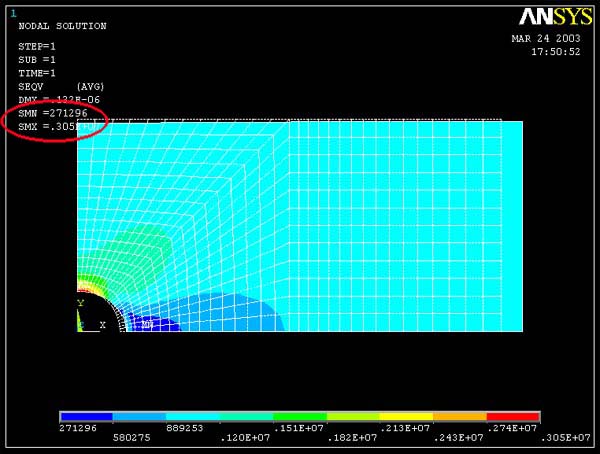

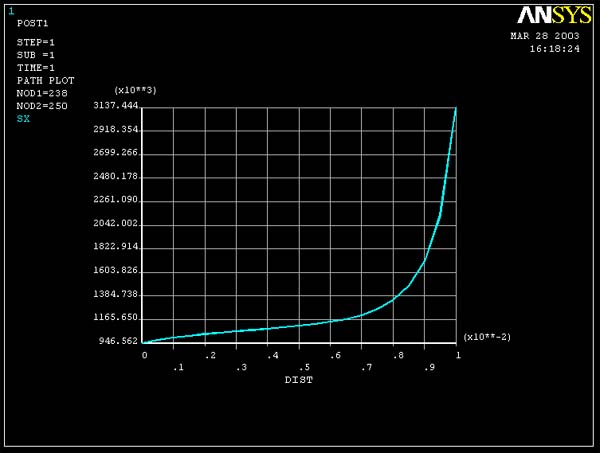

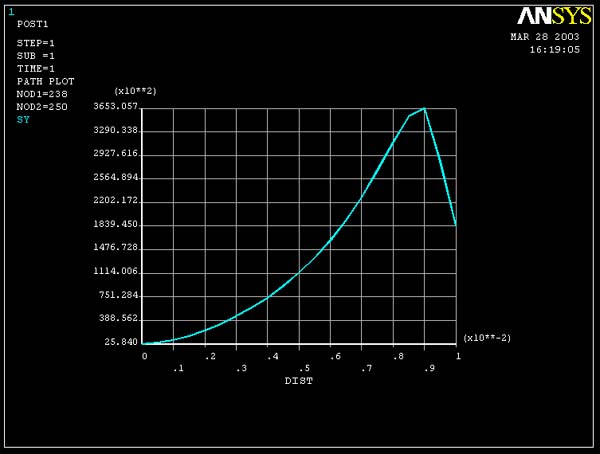

Generate a solution, then obtain results as in steps 6a - 6e. Compare results

with the ones previously obtained from auto-meshed model. Observe how the results

changed with mesh resolution.

<-----Contour Plot of stress xx

<-----Contour Plot of stress xx

<-----Contour Plot of Mises Equivalent

<-----Contour Plot of Mises Equivalent

<-----Stress

xx V.S. y

<-----Stress

xx V.S. y

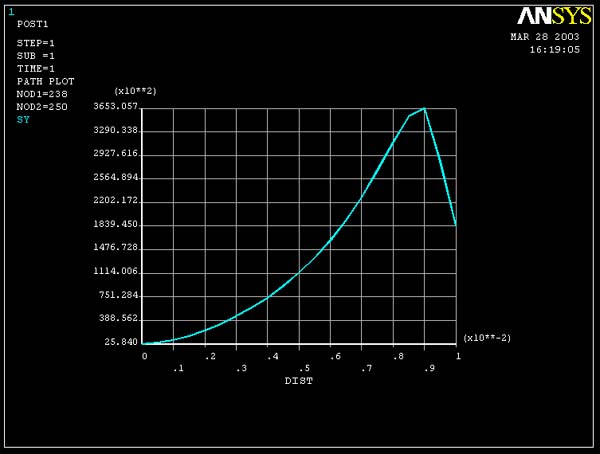

<-----Stress

yy V.S. y

<-----Stress

yy V.S. y

<-----Contour Plot of stress xx

<-----Contour Plot of stress xx <-----Contour Plot of Mises Equivalent

<-----Contour Plot of Mises Equivalent <-----Stress

xx V.S. y

<-----Stress

xx V.S. y <-----Stress

yy V.S. y

<-----Stress

yy V.S. y