8. Interpreting Your Results

The following section discusses the results from 6 element (1 along the height

and 6 along the length) and a 96 element (4 along the height and 24 along

the length) models of your beam problem.

The problem you are solving is that of a beam-shaped object under four point

bending. As a result, you would expect that beam theory would give you insight

and reasonable approximations for the axial stress Sigmaxx, the shear stress

Tauxy and the vertical displacement, v, of the neutral axis. The ANSYS code

uses the full theory of elasticity, however, and it can therefore give results

not predicted by beam theory. Also, in general, the ANSYS model will only

approach the true solution to the problem in the limit as the number of elements

is increased.

Displacement of the Neutral Axis

Beam Theory Predictions:

Beam theory predicts that the maximum displacement of the neutral axis will

occur at x = 12" and will equal:

(Pa/24EI)(3L^2

- 4a^2) ; where P is the magnitude of the applied forces = 1000 lb, a is the

the distance measured from the end of the beam to the force = 8 in, and L

is the length of the beam = 24 in.

Using the properties and dimensions of our beam, this gives a maximum displacement

in the middle of the beam of 0.0245 inches downward

ANSYS Predictions:

By extracting nodal y displacement values at the neutral axis at the center

of the beam, a 6 element ANSYS model of this problem predicts a maximum displacment

equal to: -0.024816. A 96 element ANSYS model of this problem predicts a maximum

displacement equal to: -0.024947.

Note that even though you are given a large number of significant digits in

your ANSYS results, your answer is only as accurate as the data you input

to the model. Most material properties and measurements are only accurate

to 3 significant digits, so reporting more than 3 digits in your results is

of little engineering value (and can be confusing).

Interpretation of the Results:

Beam theory yields a reasonable approximation for the neutral axis displacements

for this problem. The displacement predictions made by the 6 and 96 element

models are essentially the same.

Because the displacement predictions are not changing with element resolution,

it can be concluded that further resolution of the model is not needed to

obtain accurate displacement results. The discrepancy between the beam theory

prediction of -0.0245 inches and the ANSYS model predictions of essentially

-0.0249 inches is likely due to contributions to the displacements that the

ANSYS model is able to pick up that beam theory does not account for.

The Normal Stress Sigma xx:

Beam Theory Predictions:

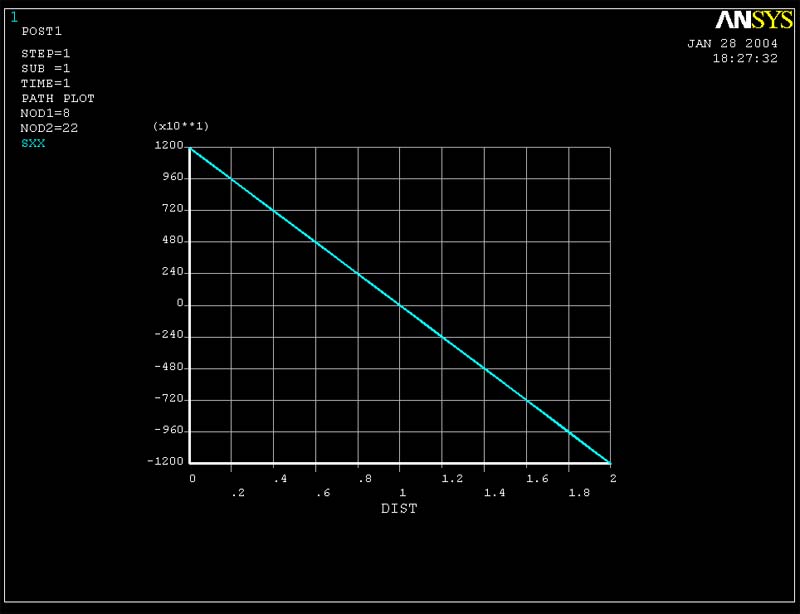

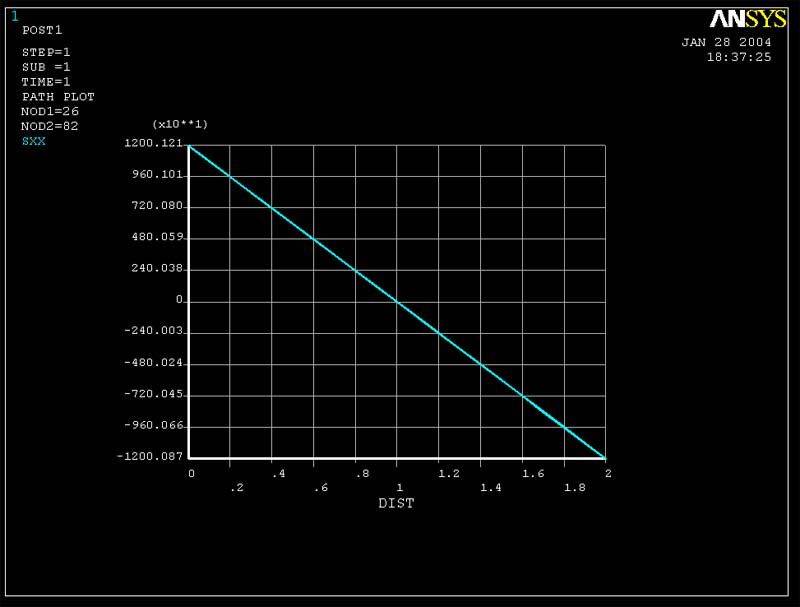

Beam theory predicts that the stress in the left 1/3 of the beam varies linearly

in x and y and is given by the formula -Pxy/I. The stress in the center 1/3

of the beam is constant in x (because the bending moment is constant there),

linear in y and is given by the formula -PLy/3I. If the loads and dimensions

of the current problem are used in the equation for Sigmaxx between the two

inner loading points, the equation that results is Sigmaxx = -12000y psi,

so that the stress magnitude at the top and bottom of the beam is 12 ksi.

Note that in a real beam, a stress of 12 ksi would not cause it to yield.

Notice that because your analysis is LINEAR, you also know the answer for

any proportional change in the applied loading. For instance, if your applied

loads were increased by a factor of 10, the maximum stress predicted by your

model would be 120 ksi. A stress of 120 ksi in a real beam would cause yielding

unless the beam were made of a very high strength steel.

ANSYS Predictions:

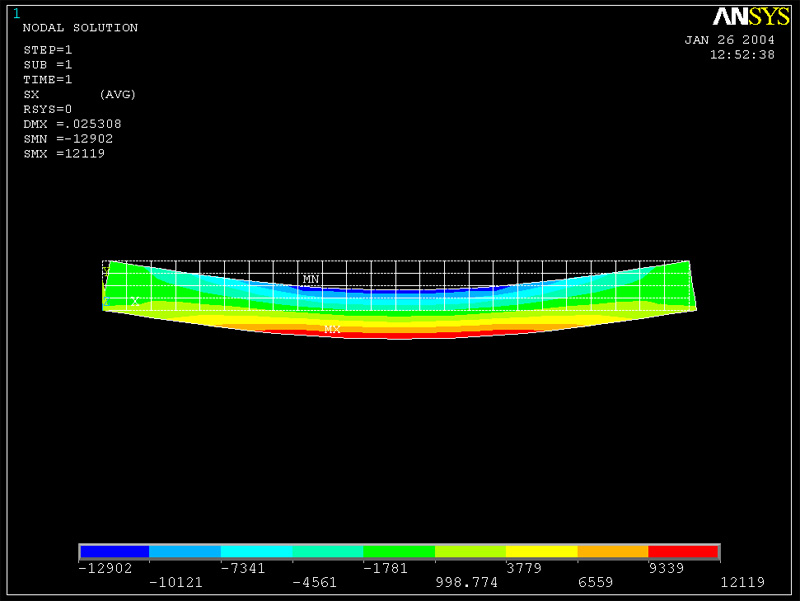

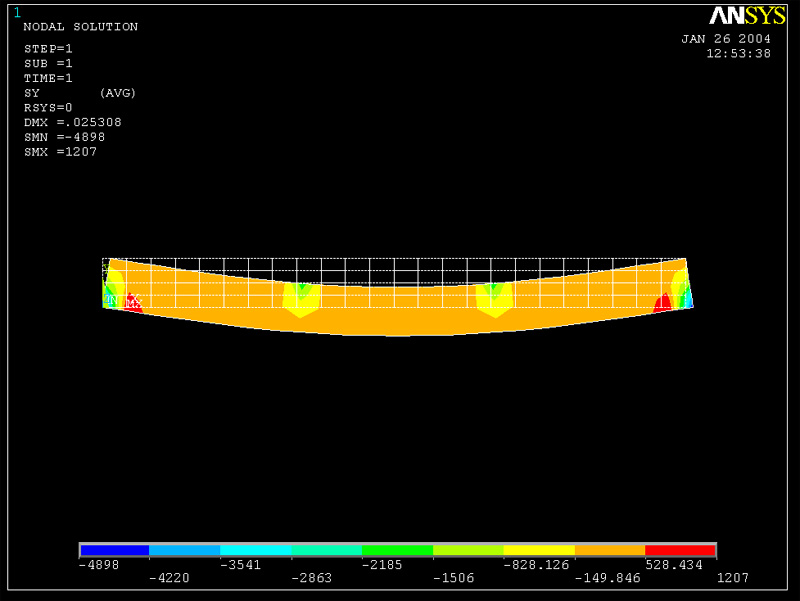

As shown in Figures 1& 2 below, qualitatively, contour plots of the stresses

Sigmaxx for a 6 element and 96 element ANSYS model show the trends predicted

by beam theory. The stress is clearly varying with x in the left and right

1/3 of the beam and appears constant in x in the middle 1/3. The symmetry

of the stresses with respect to the location x = L/2 and the antisymmetry

of the stresses with respect to the neutral axis are also apparent. The refined

model appears to be slightly better able to pick up changes in the axial stress

with location along the beam, but the 6 element model does remarkably well.

Figure 1 (Sigma xx for 6 element mesh)

Figure 2 (Sigma xx for 96 element mesh)

Figure 3 (Sigma xx vs. y for cross-section of middle of beam for 6 element mesh)

Figure 4 (Sigma xx vs. y for cross-section of middle of beam for 96 element mesh)

Interpretation of the Results:

The 6 element model is able to pick up the bending stress Sigma xx well because (according to beam theory) the stress only varies linearly with y and at most linearly in x. An 8-noded quadratic displacement element (the type you used in your model) is able to model a bilinear variation in sigma xx exactly. As a result, a single quadratic element through the thickness is sufficient for picking up this stress.

The Shear Stress Tauxy:

Beam Theory Predictions:

Beam theory predicts that the stress Tauxy in the center 1/3 of the beam is equal to zero (because the shear force equals zero there). You may also note that this is a symmetry condition. In the left and right 1/3 of the beam, the shear stress is constant in x (because the shear force does not vary in x) and varies quadratically in y (as predicted by the formula Tauxy = VQ/Ib). The maximum stress in this region is given by the formula Taumax = 3V/2A = 750 psi.

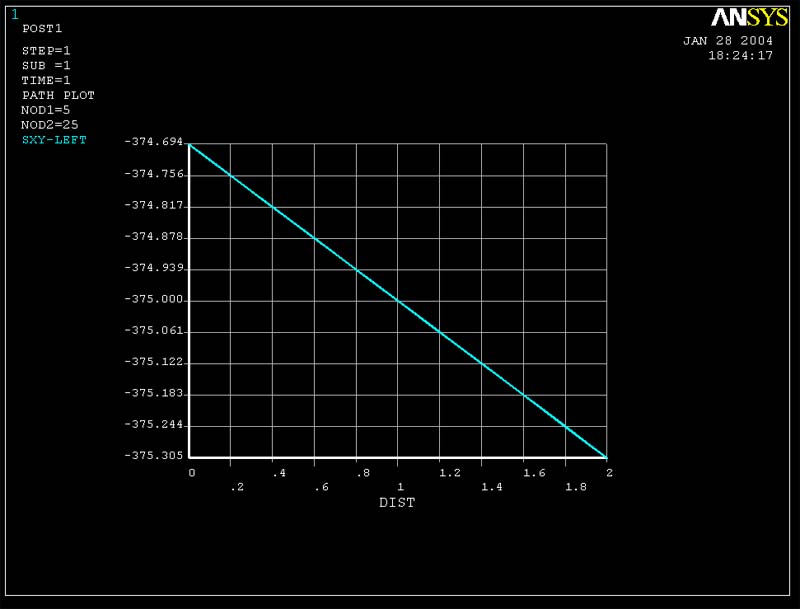

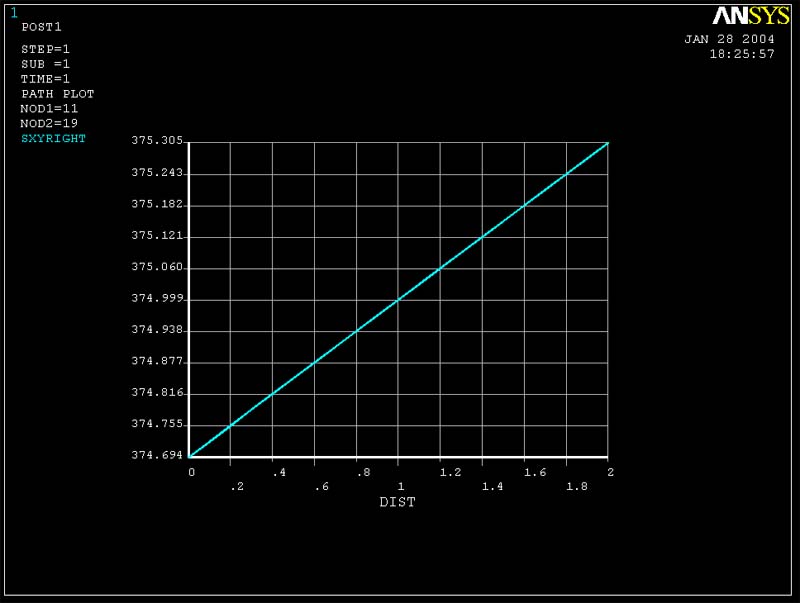

ANSYS Predictions:

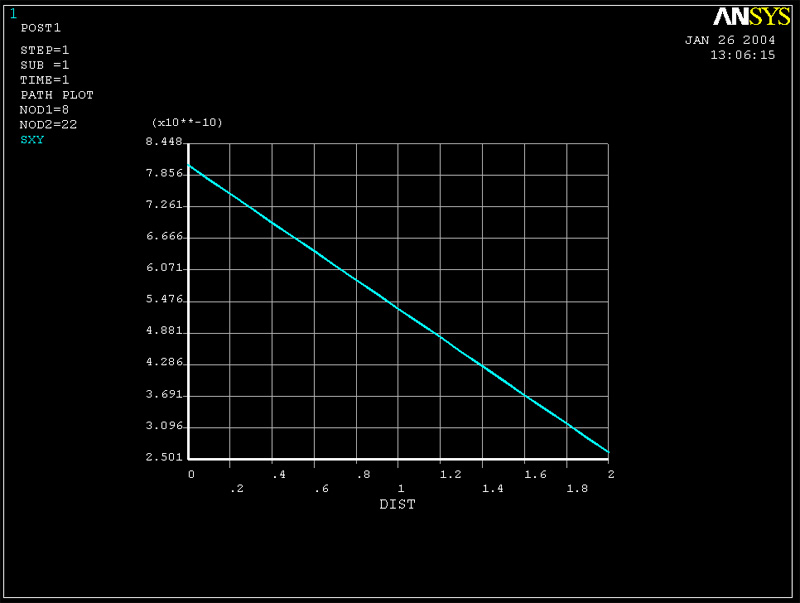

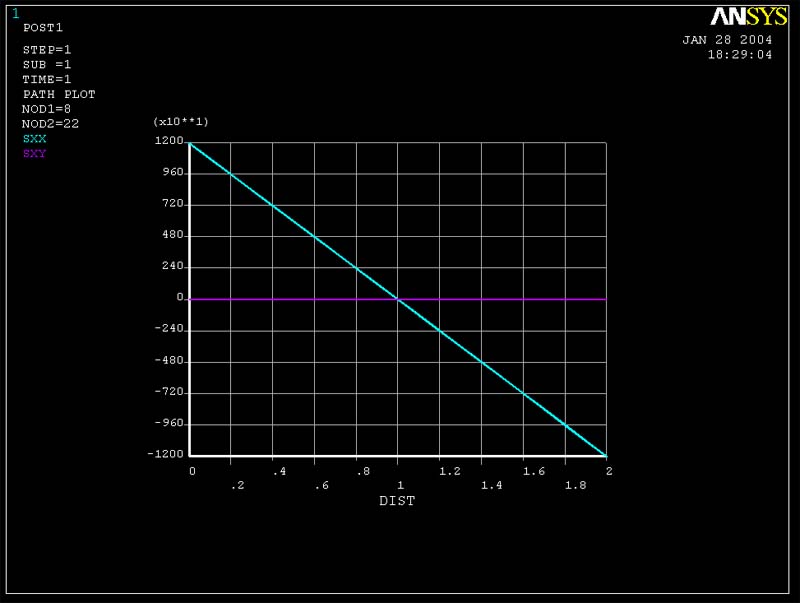

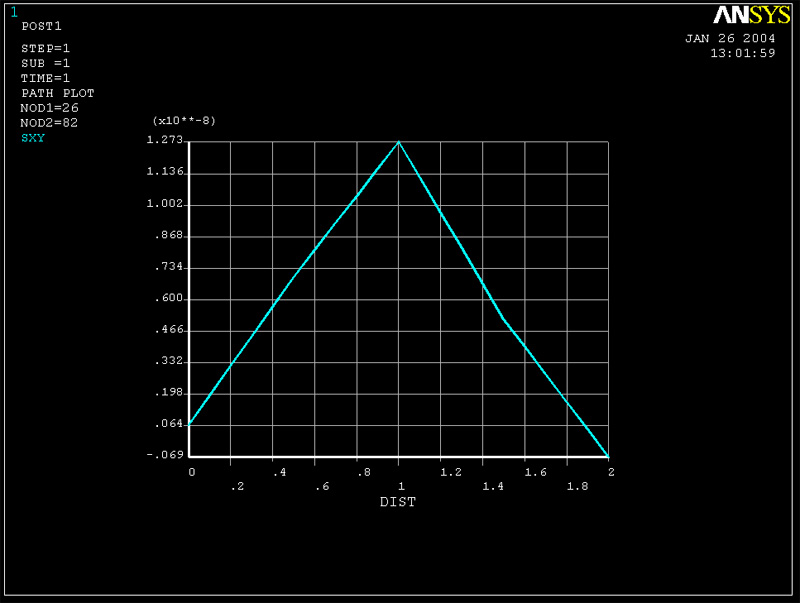

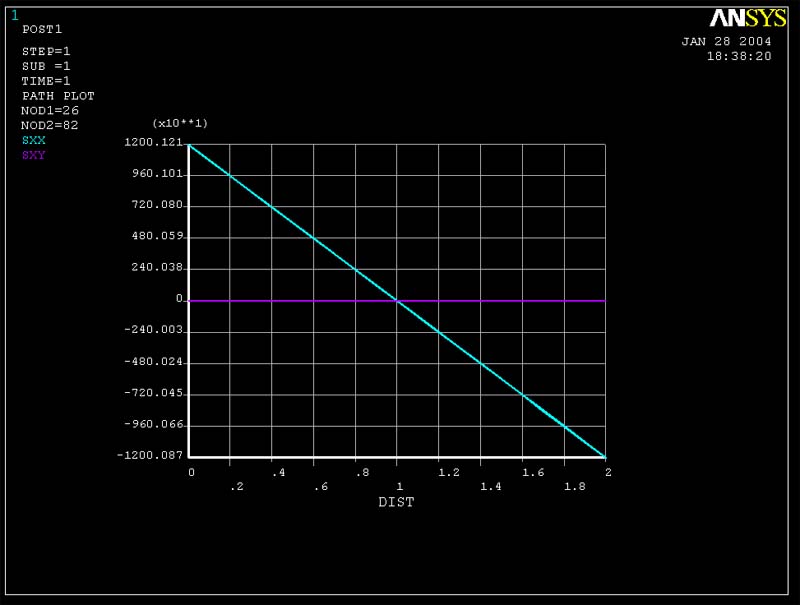

Plots of Tauxy vs. y obtained at the center of the beam are given in the two figures below. Both models are predicting essentially zero stress at this location. Don't be confused by the auto-scaling that ANSYS applies to the graph. The stress magnitudes are essentially zero.

Figure 5 (Tauxy vs. y for cross-section of middle of beam for 6 elemt mesh)

Figure 6 (Sigma xx and Tauxy vs. y for cross-section of middle of beam for 6 element mesh)

Figure 7 (Tauxy vs. y for cross-section of middle of beam for 96 element mesh)

Figure 8 (Sigma xx and Tauxy vs. y for cross-section of middle of beam for 96 element mesh)

Interpretation

of the Results:

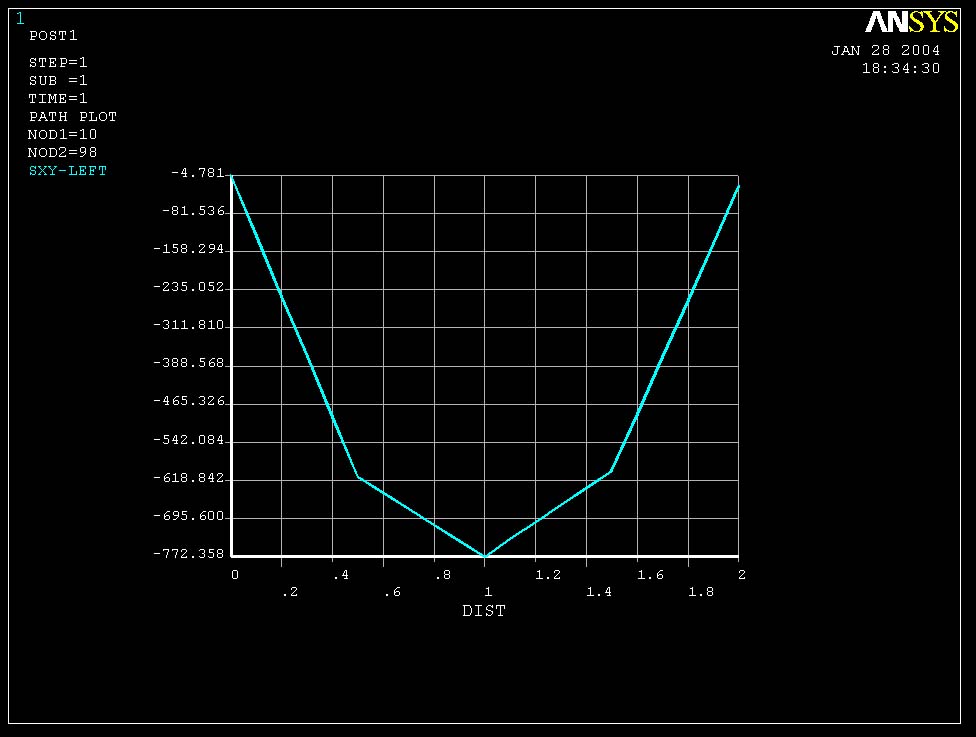

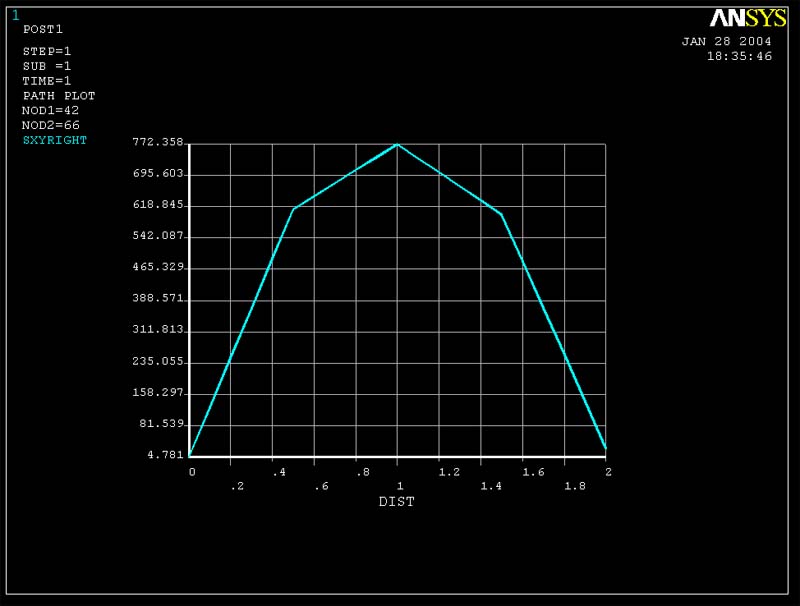

The 6 element model cannot pick up the nonzero shear stress Tauxy well. The

8-noded elements you are using are able to model accurately the quadratic

variation (in y) in strain and stress predicted by beam theory. However, in

the 6 element model, the nodes at x = L/6 are part of elements that also have

concentrated loads applied to them. Thus, these elements are also trying to

capture the very complicated behavior near these points. It is likely that

this is the source of error in the 6 element model. More insight concerning

stress concentrations at the load points is given in the next section.

Figure 9(Tauxy vs. y for cross-section at x = L/6 for 6 elements)

Figure 10 (Tauxy

vs. y for cross-section at x = 5L/6 for 6 elements)

Figure 11 (Tauxy vs. y for cross-section at x = L/6 for 96 elements)

Figure 12(Tauxy vs. y for cross-section at x = 5L/6 for 96 elements)

Effects Not Considered in Beam Theory:

Overall, the problem you have modeled is truly behaves like a beam, except

near the concentrated loads applied at the inner loading points and near the

supports. Near locations where concentrated loads are applied, a full theory

of elasticity solution to this problem will attempt to model the stress concentrations

resulting from the point loads themselves. This can be seen qualitatively

in the contour plot below of the stress Sigmayy in the 96 element model (see

Figure 11). There are clearly stress concentrations at the points of concentrated

load application.

Figure 13(Sigmayy contour plot for 96 element mesh)

Interestingly enough, a full theory of elasticity will predict singular (i.e. INFINTE) stresses at the point of application of a concentrated load. As a result, further mesh refinement will result in stresses at the location of application of a point load to become higher and higher as more elements are added. A more detailed model of contact near such a point is needed to predict stress magnitudes in a real component.

One mistake that finite element modelers make is to not recognize when their model has a singularity in it. They will simply extract a finite stress value at a singular point, obtained with a finite element model having a fixed resolution. They thus predict a large, but finite stress at this point when in fact the answer is, within the limits of their modeling, that the stresses are infinitely large.