Return

to Facilities Home Page

Three-Dimensional X-ray Diffraction Microscopy:

Seeing microstructure inside of bulk materials

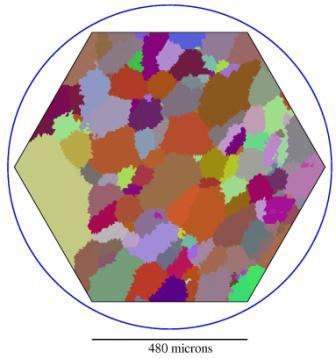

Internal layer of aluminum polycrystal measured with x-ray

diffraction microscopy at the

Advanced Photon Source (R.M. Suter,

C.M. Hefferan, S.F. Li, D.

Hennessy, C. Xiao, U. Lienert, B. Tieman, submitted ):

Colors correspond to different lattice orientations

Circle indicates 1mm nominal sample size

Hexagon indicates simulated region used in reconstruction

|

Table of Contents

- Recent publications

- Overview

- Technique summary and schematic

- Apparatus at the APS

- The July 2004 crew

Return to top

Related Publications

- Probing

Microstructure Dynamics With X-ray Diffraction Microscopy,

R.M. Suter, C.M. Hefferan, S.F. Li, D. Hennessy, C. Xiao, U. Lienert,

B. Tieman, J. Eng. Mater. Technol., 130, 021007 (2008); proceedings of

the Materials Processing

Defects-5

conference, Cornell University, July 2007).

-

3-Dimensional

Characterization of Polycrystalline Bulk Materials Using High-Energy

Synchrotron Radiation, U.

Lienert, J. Almer, B. Jakobsen, W. Pantleon, H.F. Poulsen, D. Hennessy,

C. Xiao, and R.M. Suter, Materials Science Forum 539-543, 2353-2358 (2007).

- Forward

Modeling Method for Microstructure Reconstruction Using X-ray

Diffraction

Microscopy: Single Crystal Verification, R.M. Suter, D.

Hennessy, C. Xiao, U. Lienert. Reviews

of Scientific

Instruments, 77, 123905

(2006).

-

Tracking: a

method for structural characterization of grains in powders or

polycrystals, E.M. Laurdisen, S. Schmidt, R.M. Suter, and H.F.

Poulsen, J. Appl. Cryst., 34, 744-750 (2001).

-

Three-dimensional

maps of grain boundaries and the stess state of individual grains in

polycrystals and powders, H.F. Poulsen, S.F. Nielsen, E.M.

Laurdisen, S. Schmidt, R.M. Suter, U. Lienert, L. Margulies, T.

Lorentzen, and D. Juul Jensen, J. Appl. Cryst., 34,

751-756 (2001).

- Future Trends:

Texture Analysis for Structure-Sensitive Properties, B.L. Adams, D. Juul

Jensen, H.F. Poulsen, and R. Suter, Materials Science Forum, 273-275, 29-40 (1998).

Return to top

Overview

Polycrystals are aggregates of single

crystals joined together by a network of internal interfaces called

grain boundaries. Polycrystalline materials, in both single and

multi-phase forms, are ubiquitous in engineered systems: integrated

circuits, aircraft and automotive components, communications devices,

machine tools, and many others. The three dimensional geometry,

arrangement, and relative orientation of the grains and the consequent

grain boundary network (i.e., the microstructure) are crucial

determinants of mechanical, chemical, thermal, and electrical

properties. While there has been dramatic progress made in gaining

three dimensional information about microstructure from two dimensional

measurements made at surfaces, (CMU

MRSEC) it remains a great challenge to be able to watch

microstructural evolution in response to external stimuli. With such

observations made deep inside bulk materials, we should be able to

deepen our understanding of phenomena and develop accurate constitutive

relations governing the evolution and thereby learn how to tailor

microstructures to specific applications.

Three Dimensional X-ray Diffraction

Microscopy (see articles listed

above and the monograph by H.F. Poulsen, "Three Dimensional X-ray

Diffraction Microscopy," Springer, 2004) is the only method on the

horizon that can non-destructively image macroscopic volumes of

internal microstructures. Based simply on Bragg diffraction, it is as

versatile as, for example, electron backscatter diffraction analysis of

surface microstructures. But by using high energy x-rays, it looks

through millimeters of m material. Similar to serial sectioning work,

measurements are done layer-by-layer. However, after

the measurement, the sample still exists and can be re-measured after

processing. Real-time dynamics can be monitored. The x-rays can

penetrate sample chambers, making in-situ measurements possible. In

sum, three dimensional x-ray diffraction microscopy promises to open up

the world of microstructure dynamics and response to a new light. In

combination with powerful new computational tools, one can look forward

to a new level of understanding and a new level of "dynamic three

dimensional command over materials structure," (ONR BAA 04-024)

processing, and properties.

As a part of CMU's Mesoscale Interface Mapping

Project

(MIMP) (sponsored by the NSF

MRSEC program) we are working to develop a facility for x-ray

diffraction microscopy at the Advanced

Photon Source at Argonne National

Laboratory. We are specifically working to advance the state of

non-destructive 3D microstructure mapping using high energy x-rays.

Return

to top

Schematic and Outline of the Technique

- White (multi-wavelength) synchrotron radiation from an undulator

source enters the experimental enclosure.

- Bragg diffraction from a bent single crystal of silicon (in

transmission) is used to generate a convergent monochromatic beam (50

-100keV) of x-rays.

- The line focused high energy beam (red) illuminates a ~1 micron

thick section of the sample (green).

- Bragg spots (black) from individual grains are imaged on a CCD

detector (gray); spots have the shape of the illuminated grain cross

section projected onto the detector plane at the scattering angle.

- Measuring a set of spots at multiple sample-to-detector distances

yields the path of the diffracted beam and, by inversion, the position

of

the diffracting grain.

- Step-wise measurements over a range of sample orientations, omega, yield multiple spots from

each grain; this implies complete crystallographic orientation

information and projected images of each grain from multiple points of

view.

- After image processing, our analysis code performs a simulation

of the entire measurement and microstructure. The sample space is

gridded and the crystallographic (or chemical) phase and orientation at

each grid element is adjusted to optimize the overlap

of simulated Bragg scattering with the experimental data.

Return

to top

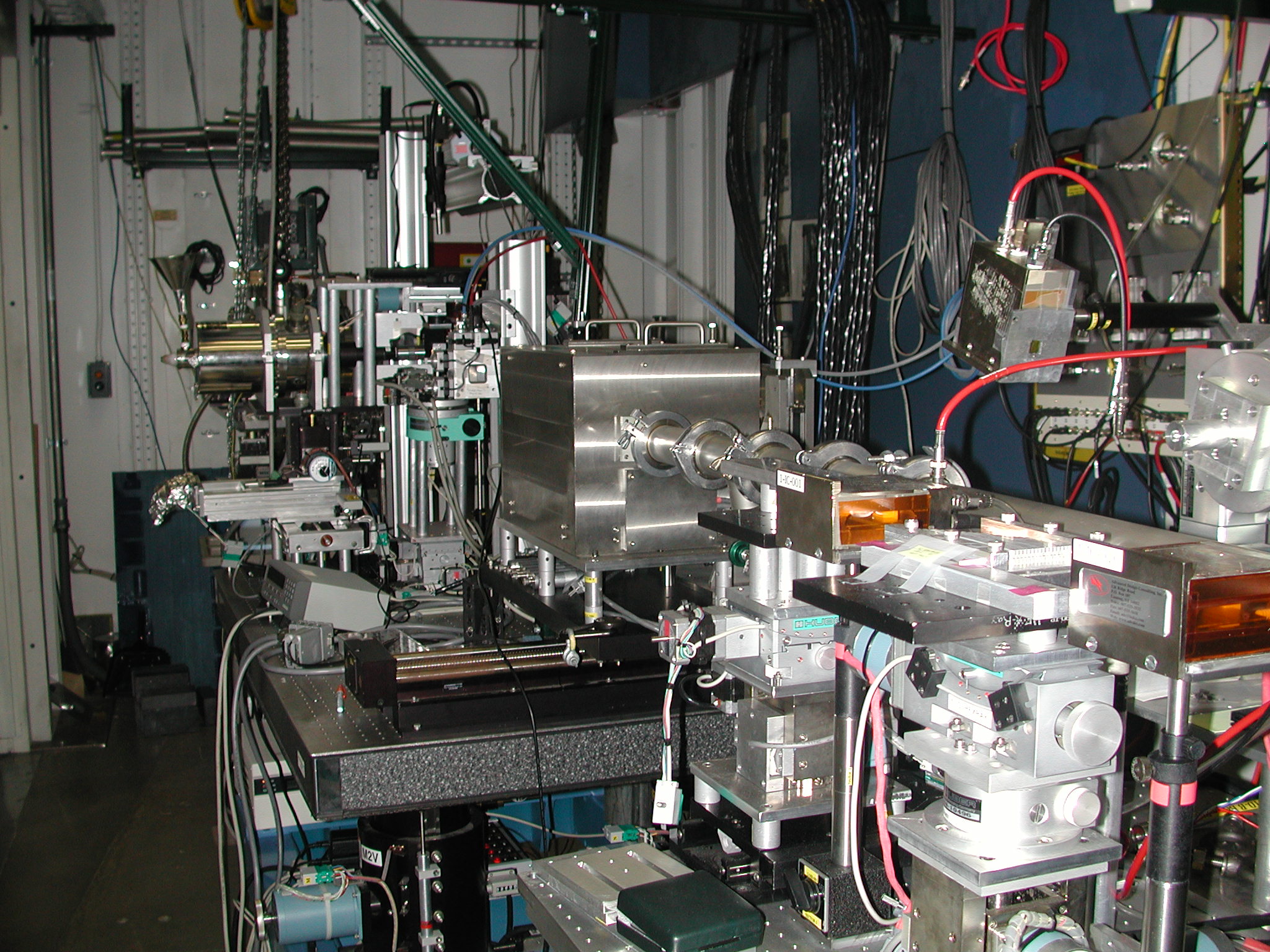

Apparatus at APS beamline XOR-1

The following images were taken during our

July 2004 beam time:

The experimental

hutch. The white beam enters from the right and travels in an evacuated

pipe into the monochromator box (roughly cubical box on optical table).

Slits before the sample (see below) reduce background and can be

used to limit the horizontal width of the line focused beam. The

sample stage and detector system follow (the horizontal stainless steel

cylinder with funnel on top is the liquid nitrogen chamber that cools

the CCD.

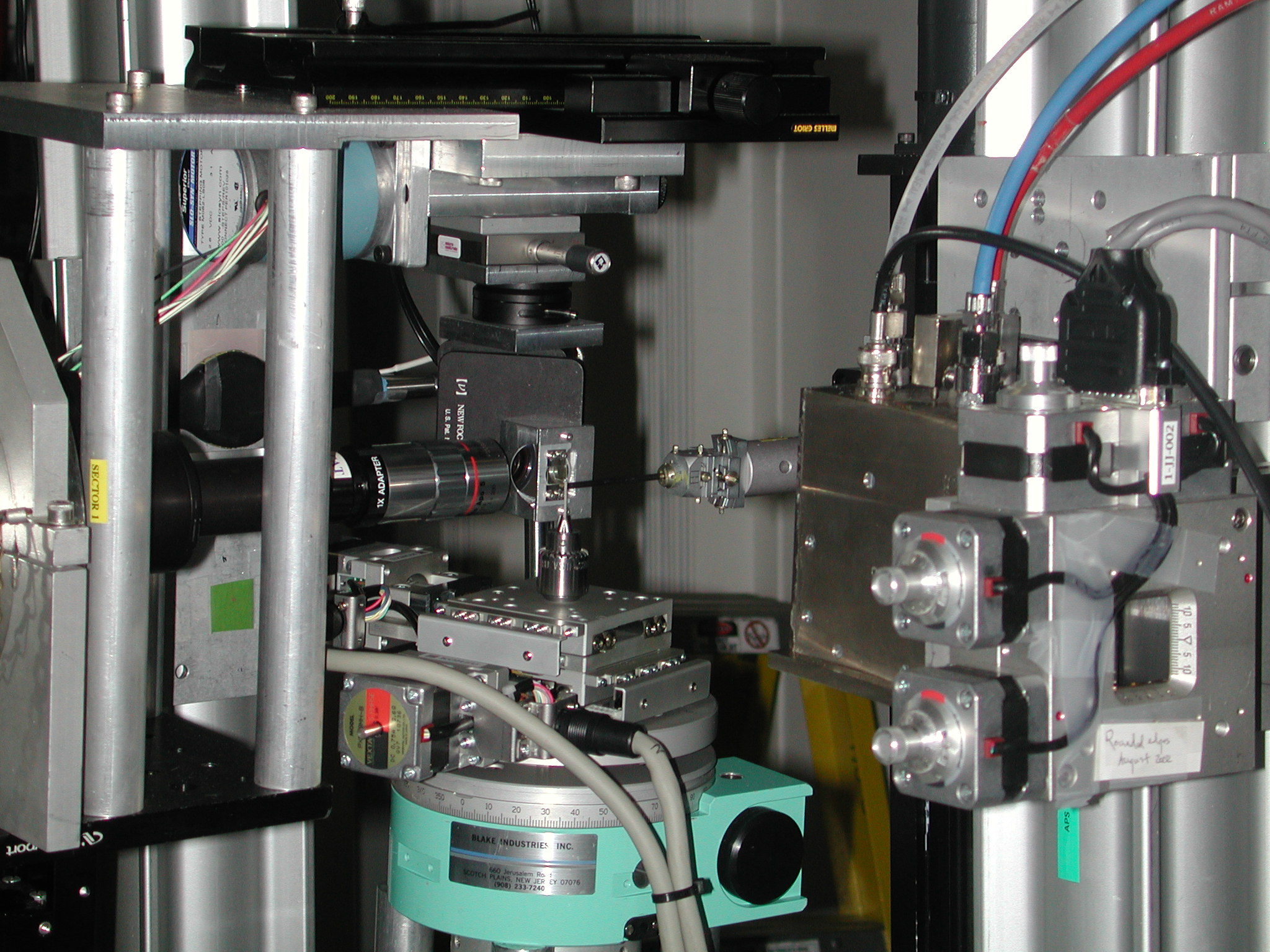

The heavy slits are at

right followed by an ion chamber for monitoring the incident beam

intensity (white, blue and red cables are attached). The sample

rotation (Huber green), omega, and translation stages (XY) are seen

next. The CCD lens (coming in from left) is pointing at a mirror that

directs light from an x-ray detector crystal (see below). The

entire CCD system is mounted on a translation stage so that the

sample-to-detector distance can be varied.

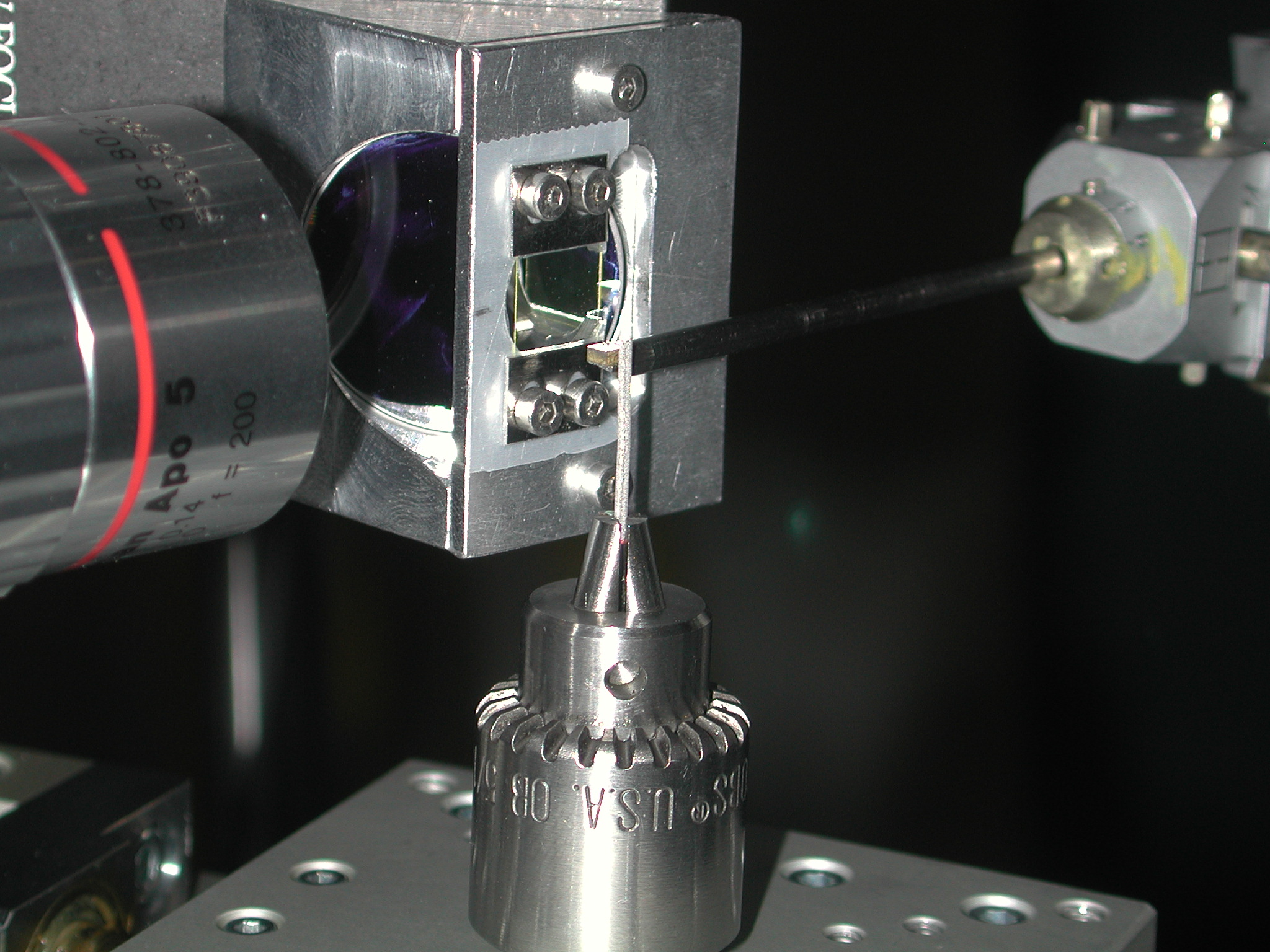

Close-up of a mounted

sample (in the drill chuck), Ta beam stop (perpendicular to sample and

mounted in a goniometer at right), transparent x-ray detector crystal

(Ce doped YAG), mirror, and lens that couples light to the CCD (out of

view to left).

Return to top