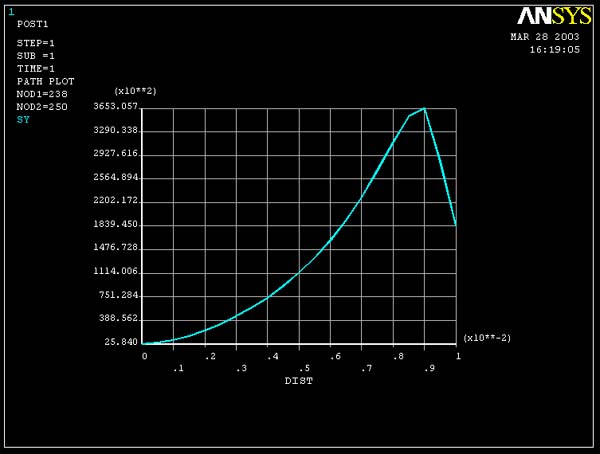

8. Interpreting Your Results

In this step, we will compare the results of the coarse-meshed plate with those

of the fine-meshed plate. The results we are going to consider are :

1. Contour

Plots of the Stress xx: Maximum and Minimum Stresses xx

2. Contour Plots of the Mises Equivalent

Stress : Relate to Von Mises Yield Criterion

3. Stress xx across the cross section (At

x=0)

4. Stress yy across the cross section (At

x=0)

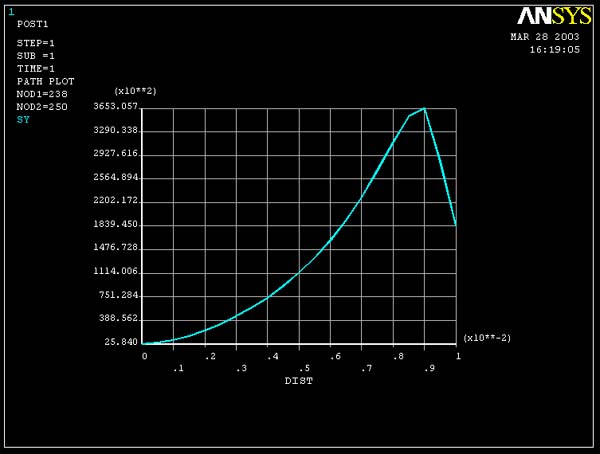

Maximum

and Minimum Stresses xx :

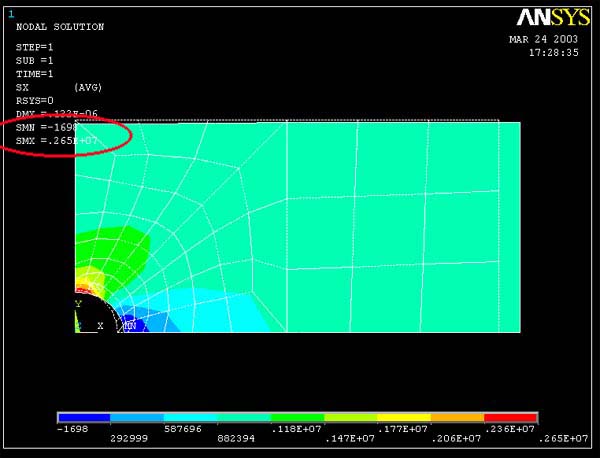

Result of free mesh (coarse) model :

|

<---

Contour Plot of Stress xx

Maximum Stress xx = 0.265E+7 Pa

Minimum Stress xx = -1698 Pa |

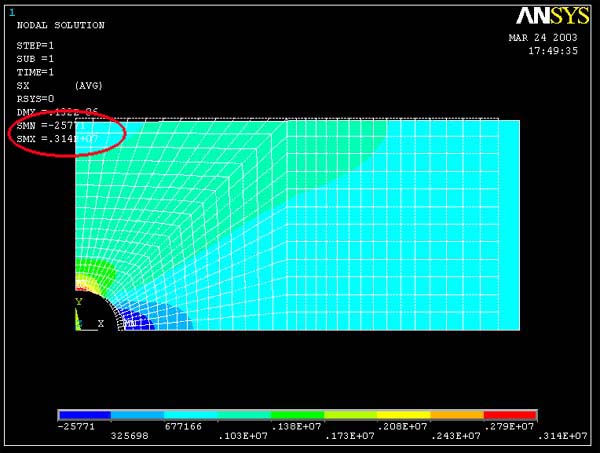

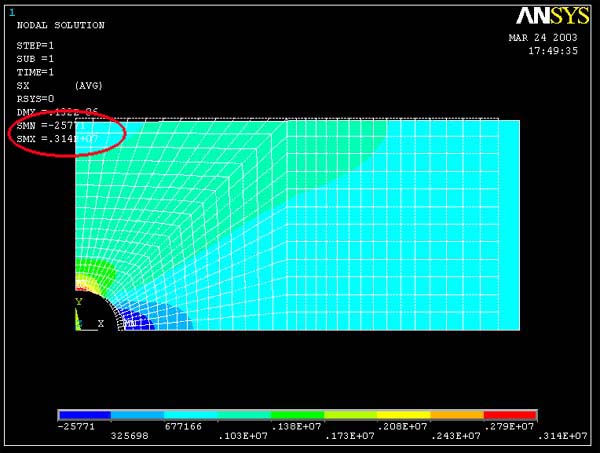

Result of mapped mesh (refined) model :

|

<---

Contour Plot of Stress xx

Maximum Stress xx = 0.314E+7 Pa

Minimum Stress xx = -25771 Pa |

Interpretation of the Results:

1. As shown in both figures above, the top point of the

hole (The red area) has positive (tensile) stress, while the point on the right

edge of the hole has a compressive stress. This is consistent with what is seen

in the closed-form solution for a hole in an infinitely large plate under far-field

uniform tension. Note that the dash lines represent undeformed shape of the plate.

2. With higher mesh resolution, it is clear that the stress contour lines are

smoother.

3. According to The

Stress-concentration factor chart of a finite-width plate with a circular hole

(Peterson, 1974), K = 3.14, where K = Stress_max/P, where P = Pressure

Load and a/w = 0.2. The stress-concentration factors K for both cases obtained

using maximum stresses obtained from the contour plots are:

K_free = 2.65

K_map = 3.14

From these results, it is clear that the higher mesh resolution gives more accurate

results.

Von Mises Equivalent Stress :

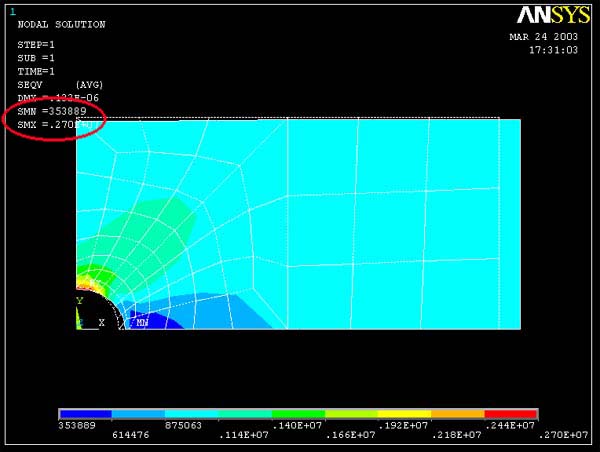

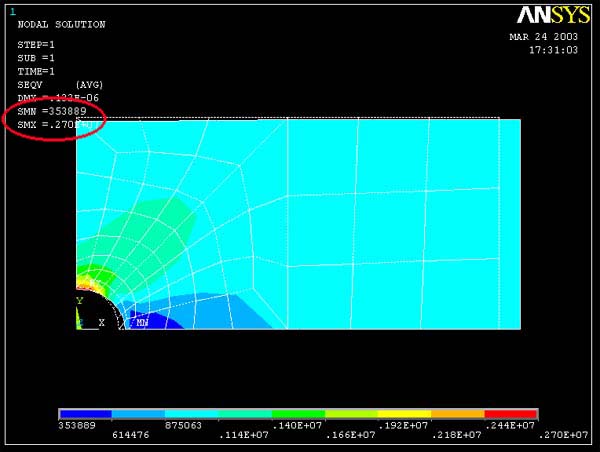

Result of free mesh (coarse) model :

|

<---

Contour plot of Mises Equivalent Stress

Maximum SEQV = 0.270E+7 Pa

|

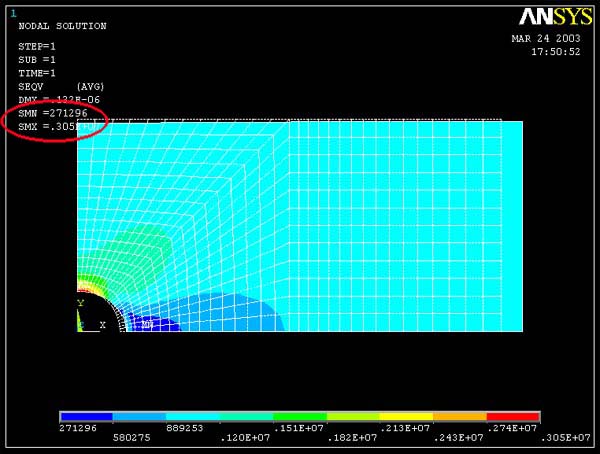

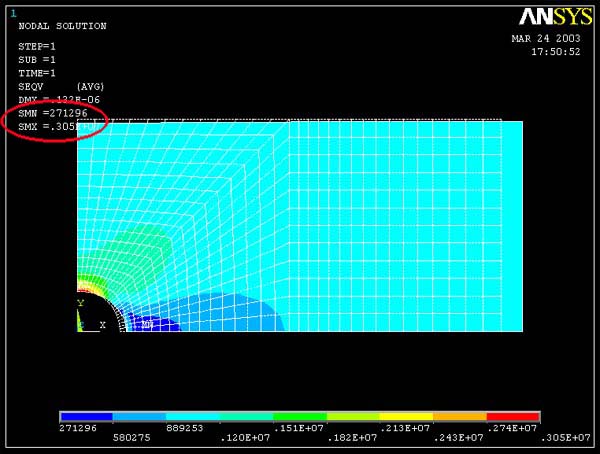

Result of mapped mesh (refined) model :

|

<---

Mises Equivalent Stress

Maximum SEQV = 0.305E+7 Pa

|

Interpretation of the Results:

1. As with the stress xx, with higher mesh resolution, the

lines separating the Von Mises Stress contours are smoother.

2. In each case, the maximum Von Mises Stress occurs at the edge of the hole as

expected. At this point, the stress state is uniaxial, so that the Von Mises Stress

equals the stress xx. The differences between the Von Mises Stress and the stress

xx in the FEA models is due to the models not precisely picking up the traction-free

boundary condition at the hole boundary.

3. In applying the Von Mises Yield criterion, yielding is predicted to occur when

Mises Equivalent Stress(maximum) = Yield Stress.

Yield Stress_free = 0.270E+7 Pa

Yield Stress_map = 0.305E+7 Pa

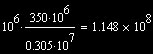

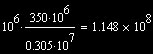

This for a yield stress of 350 MPa, initial yielding will occur when the applied

load equals :

=115 MPa

4.

Note also that the initial yielded zone near the top edge of the hole will look

like the Von Mises contour lines. There will be some difference, though, because

an actual yielded plate will experience some load redistribution due to yielding.

The only way to precisely track the boundary between yielded and unyielded material

as the load is increased is to perform a more complicated elastic-plastic analysis.

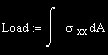

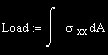

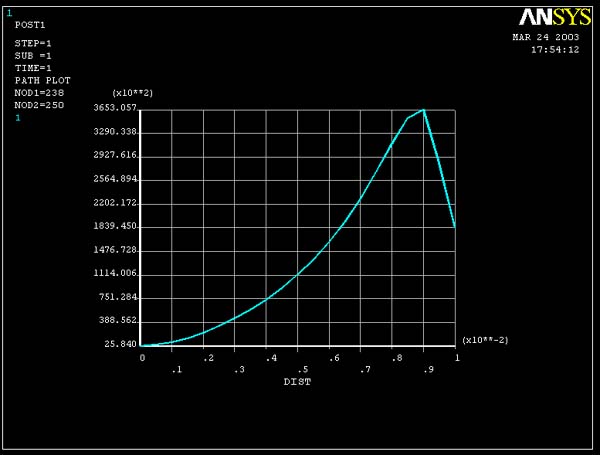

Stress

xx across the cross section :

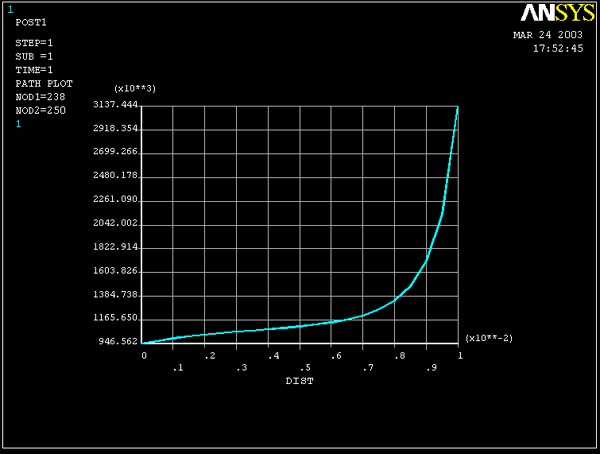

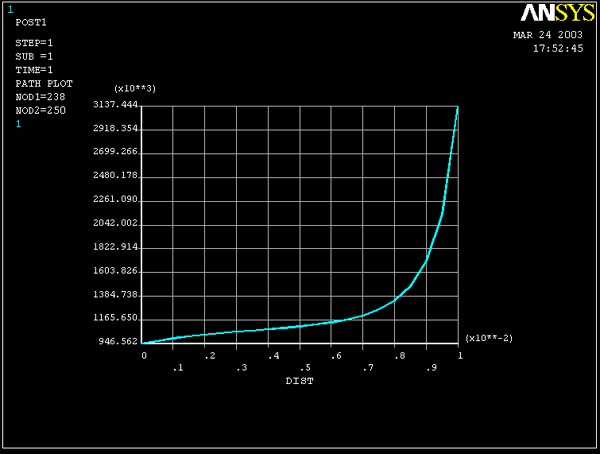

Result of free mesh (coarse) model :

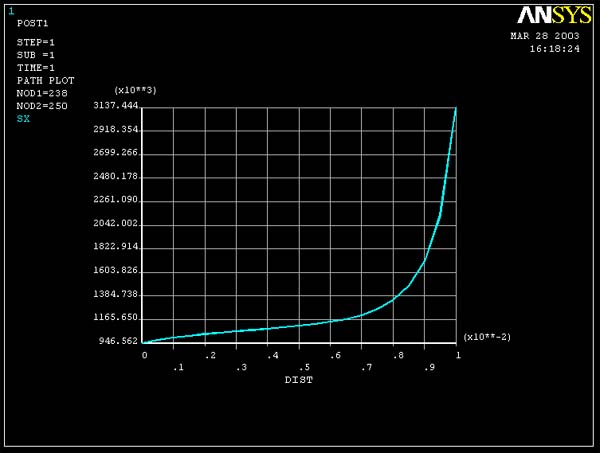

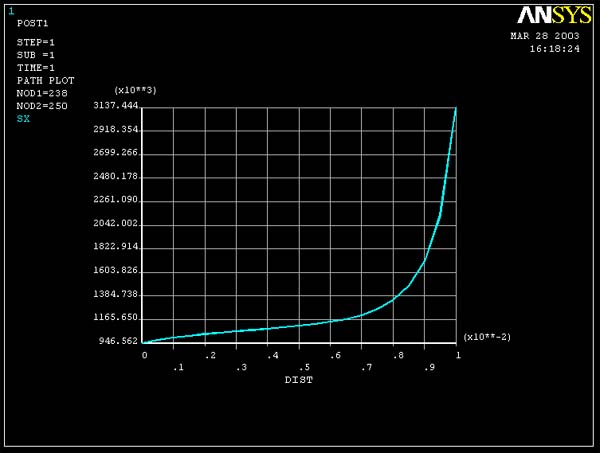

Result of mapped mesh (refined) model :

Interpretation of the Results:

1. With higher mesh resolution, the graphed line is smoother

and the maximum value is larger.

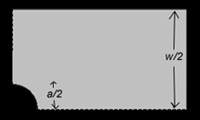

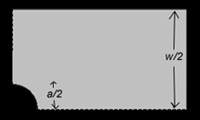

2. The average stress xx across the cross section can be calculated by using the

following formula :

|

Where

P = Pressure Load

w = Width of the plate

a = Diameter of the hole |

|

With

values P=1000000 Pa, w = 0.025, a = 0.005, The average Stress is 1,250,000 Pa.

This is also the "average" stress in the plots of the stress xx VS y.

The effect of the hole is to elevate the stress to a value above the average for

locations near the hole, and to reduce the stress to a value below the average

for locations away from the hole. Another way of thinking of this is that the

area under the stress xx VS y curve is the total load carried by the unit-thickness

plate, i.e.

For a given applied load, introducing a stress concentration simply changes the

distribution of the stress xx, but the area under the curve is the same.

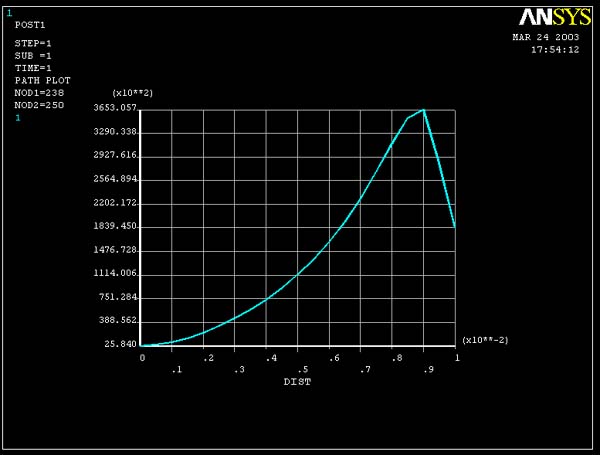

Stress yy across the cross section :

Result of free mesh (coarse) model :

Result of mapped mesh (refined) model :

Interpretation of the Results:

1. As for the stress xx, with higher mesh resolution, the

graphed lines of the stress yy is smoother.

2. From your knowledge of boundary conditions, you know that the stress yy is

zero at the edge of the plate and at the edge of the hole. The FEA solution will

capture this boundary condition only in the limit of a highly refined mesh. You

can see that the refined mesh is doing a better job at capturing the traction-free

boundary condition at both edges. Although the refined model is still showing

significant stress yy at the hole boundary, this discrepancy does not seem to

be significantly affecting values of the stress xx or the Von Mises Equivalent

Stress.